Do you want the service life of the blade during cloth cutting?

In terms of rotary cutter blade, Fiskars, a well-known brand from Finland, and Olfa of Japan are the leaders in this industry. However, our rotary cutter Blades are not only comparable in quality to these top international brands, but even better in some aspects, such as excellent cost effectiveness. Fiskars leads the market with high production volumes, Olfa focuses on precision craftsmanship, and our blades find the perfect balance of durability, sharpness and cost performance.

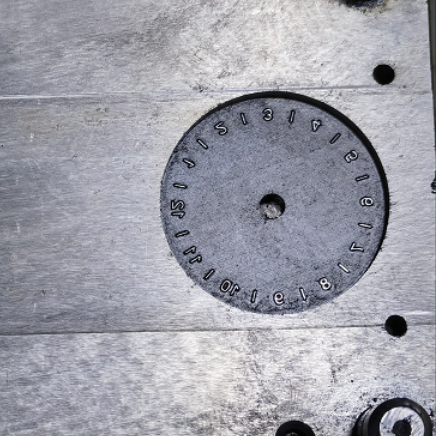

We are a raw material manufacturer with our own steel plant. Unlike most brands of externally sourced materials, we use SKS-7 high-carbon tool steel, which gives us greater control over the properties of the steel. Thanks to our unique heat treatment process for SKS-7 steel, the life of the subsequent machining into blades is longer.

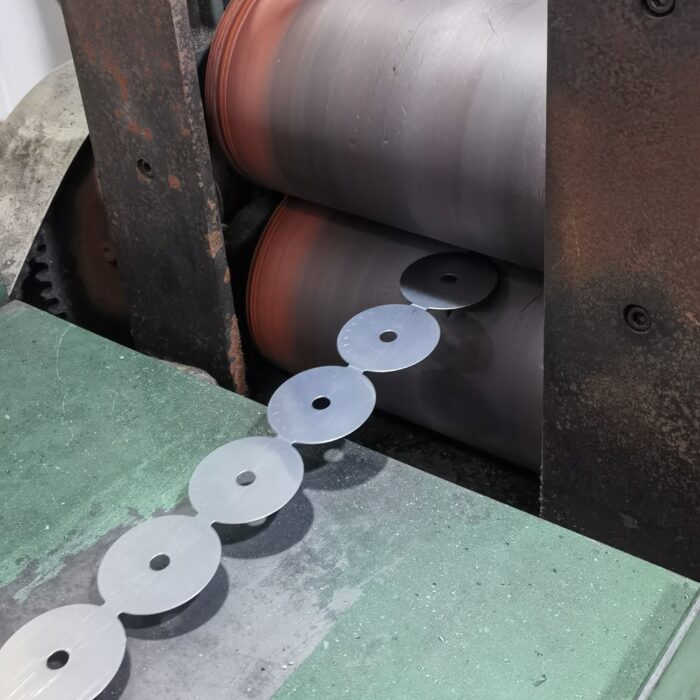

We cooperate with the matching brother factory, through the professional grinding process, not only to ensure the blade cutting smooth and accurate, will not produce rough edges in the cutting process, and increase the utilization rate of the blade. This is especially important for users who need to maintain sharp edges for long periods of time or for the film, paper products and crafts industries.

Although other brands such as Fiskars and Olfa have high prices due to their global popularity, we are a direct manufacturer, from raw material to finished product supplier, and this direct production method allows us to provide you with higher quality rotary cutter blades at highly competitive prices.

| C | Cr | Mn | Si | Mo | V |

| 1.10~1.20 | 0.20~0.50 | ≤0.50 | ≤0.35 | 0.40~0.70 | ≤0.20 |

| Cu | S | P | Ni | Nb | W |

| ≤0.25 | ≤0.03 | ≤0.03 | ≤0.25 | – | 2.00~2.50 |

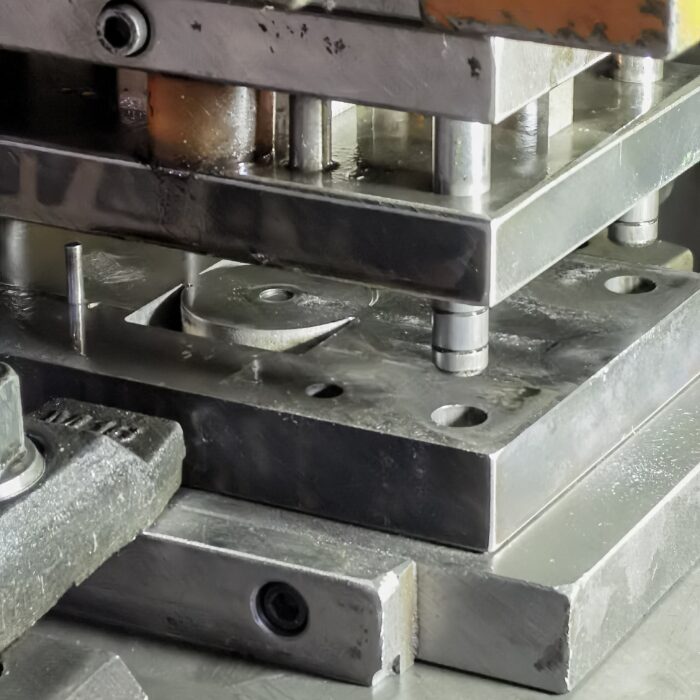

1.Double guarantee cutting effect: plane grinding can ensure the flatness and smoothness of the blade surface, reducing the resistance during cutting, and vertical grinding makes the blade edge sharper, making each cutting smooth.

2.Prolong the service life of the blade: Flat grinding makes the surface of the blade more uniform, reducing the possibility of wear; The vertical grinding ensures the stability of the cutting edge under high load, avoids premature passivation of the blade, and greatly extends the service life of the blade.

3.High precision cutting for a variety of materials: The combination of flat and vertical grinding makes the blade not only suitable for precise cutting of soft materials such as cloth and leather, but also suitable for handling hard materials such as cardboard and thin boards, with fine cutting effect and smooth edges.

4.Higher safety and operating comfort: The blade with flat vertical grinding has a smoother surface and sharper edge, which is not easy to get stuck when cutting, reducing instability in operation and improving safety.

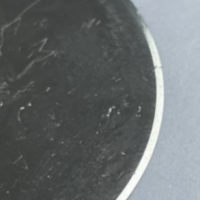

Using a high-power lens to zoom in on the cutting edge of the blade, you can see the smoothness and accuracy of the blade. High quality edges should be free of any notches or burrs and have a smooth and flat surface. High-quality blades usually have a uniform, fine grinding texture, while inferior blades will have irregular grinding marks, rough surfaces and even dents.

| Edge width(Projection) | 0.76-0.77 |

| Edge Angle | 21°(Two-sided) |

| Outside diameter of knife edge | 44.93-44.96 |

| Hardness | 92.6 |

| Edge width(Projection) | 0.75-0.77 |

| Edge Angle | 21°(Two-sided) |

| Outside diameter of knife edge | 45-45.02 |

| Hardness | 92.7 |

Test cutting: In the actual cutting process, you can observe the performance of the blade, high-quality blades can maintain sharp under high load, cutting smoothly. On the contrary, inferior blades will wear seriously in a short period of time, resulting in stalling or resistance during cutting, and the cut material may be irregular or have burrs, affecting work efficiency and the appearance and quality of the finished product.

Showcasing their exquisite craftsmanship and high-performance features. We are committed to delivering quality products to ensure we meet our customers’ needs.