ZEICIN is committed to the high-end positioning of China’s quality. As a branch of Zhejiang Zhengda Mould Co., Ltd., we specialize in the export and customer service of high-quality, cost-effective products, helping customers save operational costs. Founded in 2003, our factory is located in Jinyun County, Zhejiang Province, covering an area of over 60,000 square meters.

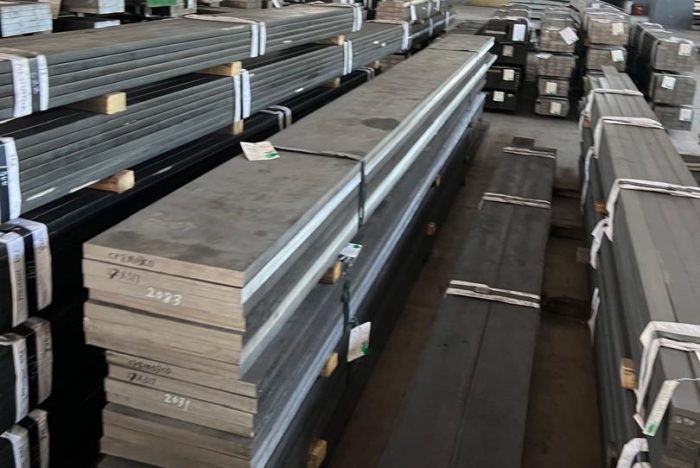

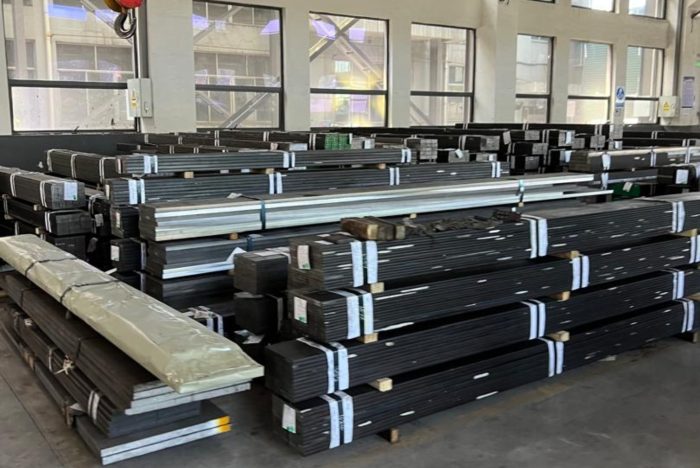

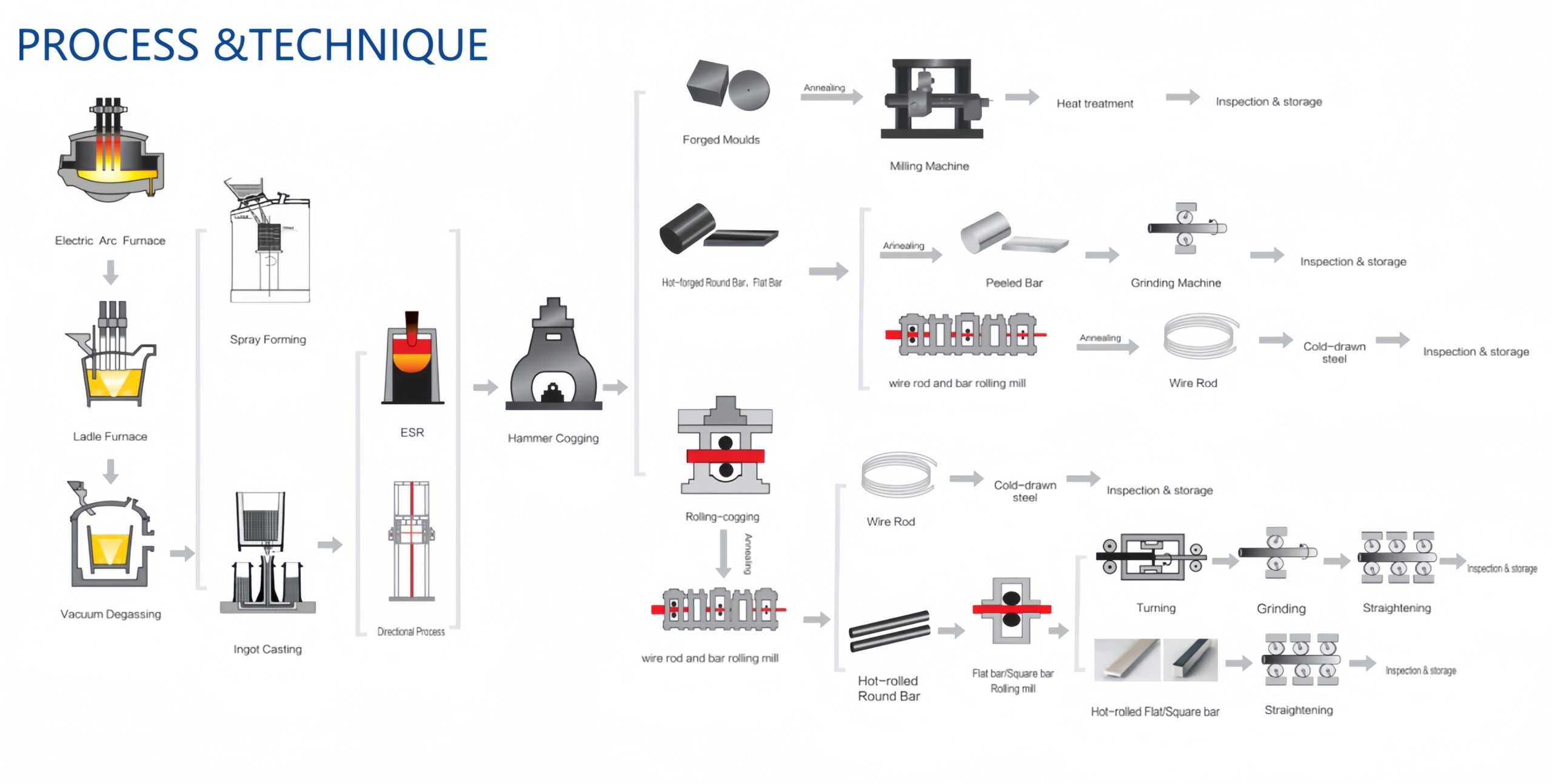

We integrate advanced processes such as smelting, electroslag re-melting, forging, hot-rolling, drawing, heat treatment, and finish machining to produce a wide range of tool and die steel products, including round bars, flat bars, cold-drawn steel wire, hot-rolled steel strips, HSS mold products, and plane cutter white steel knives.

At the heart of our ethos is a dedication to integrity and the cultivation of mutually beneficial partnerships. We understand that success is not achieved in isolation; rather, it is the result of collaborative efforts and a shared commitment to excellence. By prioritizing transparency, reliability, and ethical conduct, we aim to forge enduring relationships with our clients and stakeholders based on trust and mutual respect.

At ZEICIN, our overarching goal is to continually enhance our capabilities and expand our product offerings to meet the evolving needs of our customers. Through ongoing research and development initiatives and a keen focus on customer feedback, we remain at the forefront of innovation, ensuring our solutions remain relevant and impactful in an ever-changing market landscape.

ZEICIN represents more than just a manufacturer; we are a symbol of Chinese ingenuity and craftsmanship, driven by a passion for excellence and a commitment to customer satisfaction. Whether you are seeking cutting-edge tools or reliable components, you can trust ZEICIN to deliver uncompromising quality and value, every time.

The company has a strong technical team, and has developed the following five major inventions and technological achievements:

Innovating the new technology of rapid solidification electroslag remelting

High-speed steel new technology process of three pressure three drawing for big size round bar

The processing method of rare earth elements modification is won the national invention patent

The new technology of hot-work die steel double refining is obtained the second prize of Shanghai scientific and technological

Unique spray forming technology and facilities of devoting itself to R&D

The company has long-term cooperated with Shanghai University and Beijing Iron Steel Research Institute, and taking charge of the project issues of leading by Shanghai University of Science and Technology, “thirteen five” national key R & D program “, focus on basic materials technology upgrading and industrialization, special focus on the application of high-performance tool and die steel.

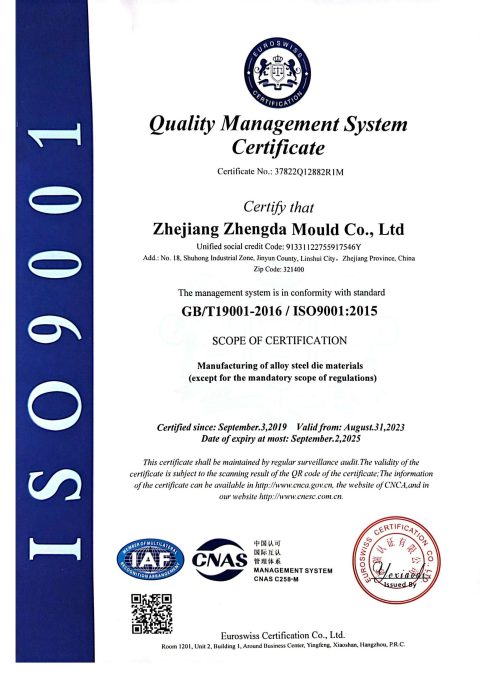

We have passed the ISO9001:2008 Quality Management System Certification and implemented strict quality assurance measures to ensure the highest product standards.

At ZEICIN, we are dedicated to delivering high-end Chinese quality through our unique RS ESR (Rapid Solidification Electroslag Remelting) innovative technology and over 20 years of expertise in producing tool steels and knife steels. Here’s why we stand out:

.

great works

Invention Patent Certificate

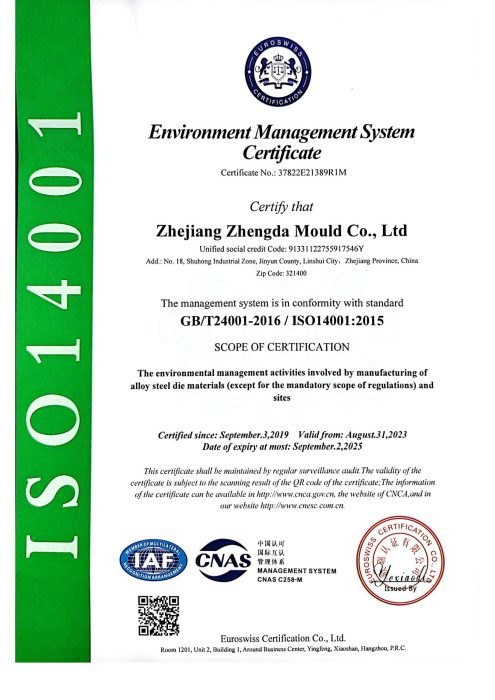

Environmental Management System Certificate

National key research and development plan of the 13th five-year plan

Invention Patent Certificate

Utility Model Patent Certificate

Our company boasts strong technical capabilities and has successfully developed the domestically original Rapid Solidification Electroslag Remelting (RS ESR) technology and the Three Pressures and Three Draws process for high-speed steel round bars. The rare earth element modification method has been awarded a national invention patent. We are committed to producing excellent products and strive to be a leading enterprise in the “Made in China 2025” initiative for quality manufacturing.

Our Rapid Solidification Electroslag Remelting (RS ESR) technology endows steel ingots with the following characteristics:

This technology ensures that our steel ingot materials outperform domestic counterparts in wear resistance, red hardness, and toughness, while also surpassing imported materials in carbide size and distribution.

Our technical advantages are reflected in the following aspects:

Through these technologies, we are able to provide customers with high-performance, cost-effective products, helping them gain a competitive edge in the market.