ZDF-T1016 is a high-speed steel (HSS) premium with high wear resistance for industrial applications.Comparable to the renowned Japanese M42, this material not only focuses on durability but also extreme wear resistance and long tool life for cutting tools, punches, and saw blades.

| C | W | Mo | Cr | V | Co |

|---|---|---|---|---|---|

| 1.05-1.15 | 7.00-8.00 | 5.20-5.70 | 3.50-4.20 | 1.60-2.00 | 8.75-9.25 |

| Type | Specification(mm) | Surface condition |

| Hot-rolled Round Bar | Φ10.5-φ65 | Ground/Turned |

| Cold-drawn Steel Wire | Φ2.0-φ13.5 | Ground/Polished/Black |

| Band saw blade wire | 1.13*1.4 etc. | No decarbonization |

Extended Tool Life & Cost Efficiency

Most tools (ZDF-T1016 high-speed steel taps, drills, etc.) can increase tool service life by more than 50% compared with the domestic M42 materials, to reduce tool replacement times, and improve production efficiency.

ZDF-T1016 high-speed steel has excellent strength and toughness in the hardness range of HRC67-69, and is particularly used in high hardness tensile punch bar and other aspects with high performance requirements.

The unique chemical composition and heat treatment process of ZDF-T1016 high-speed steel ensures that it still has excellent high-temperature wear resistance and hardness, thus ensuring stable and reliable tools during high-speed cutting.

Its hardness and toughness make ZDF-T1016 best for cutting tools and precision punches.

The optimized chemical composition, including tungsten, molybdenum, and cobalt, ensures superior wear resistance and red hardness, even in high-temperature environments.

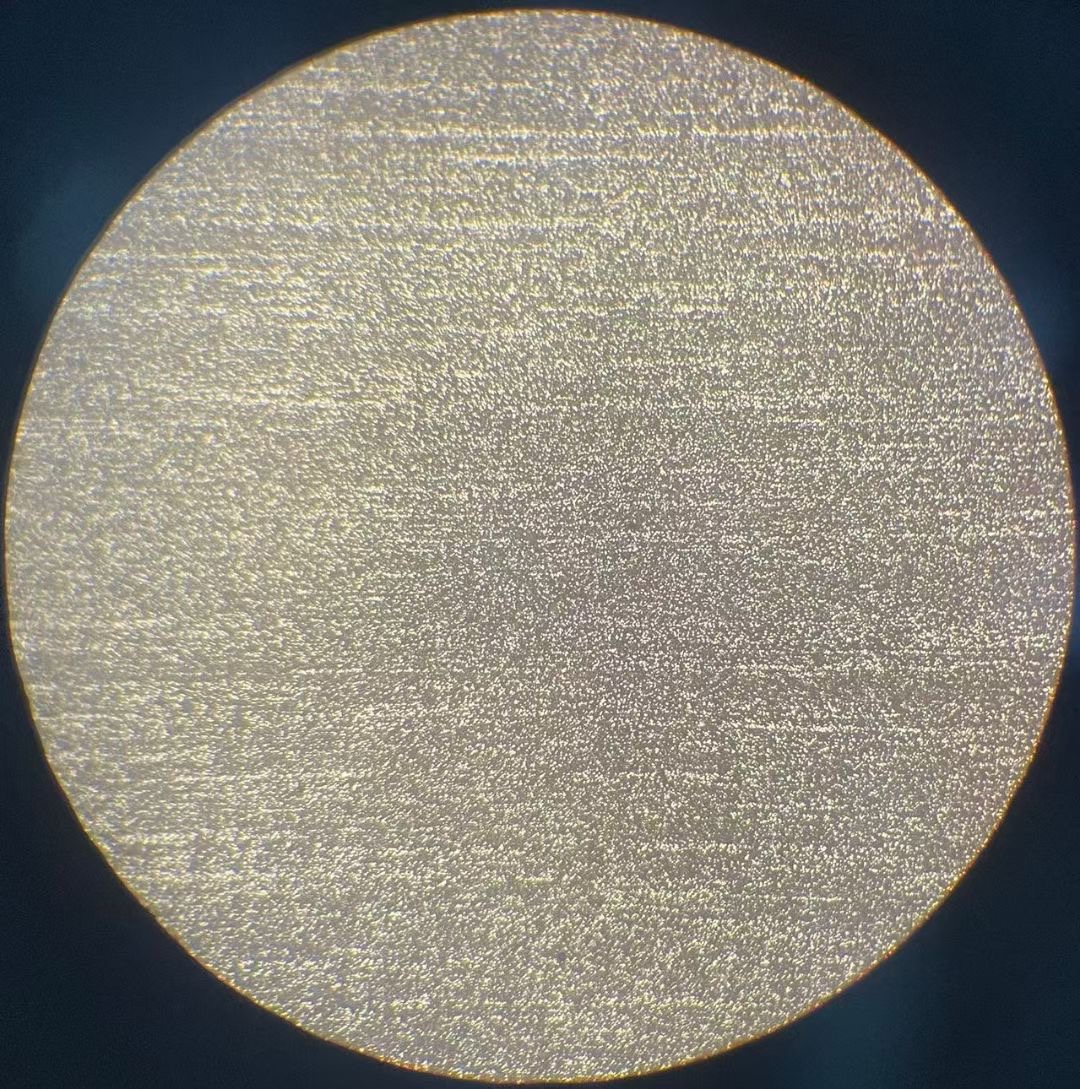

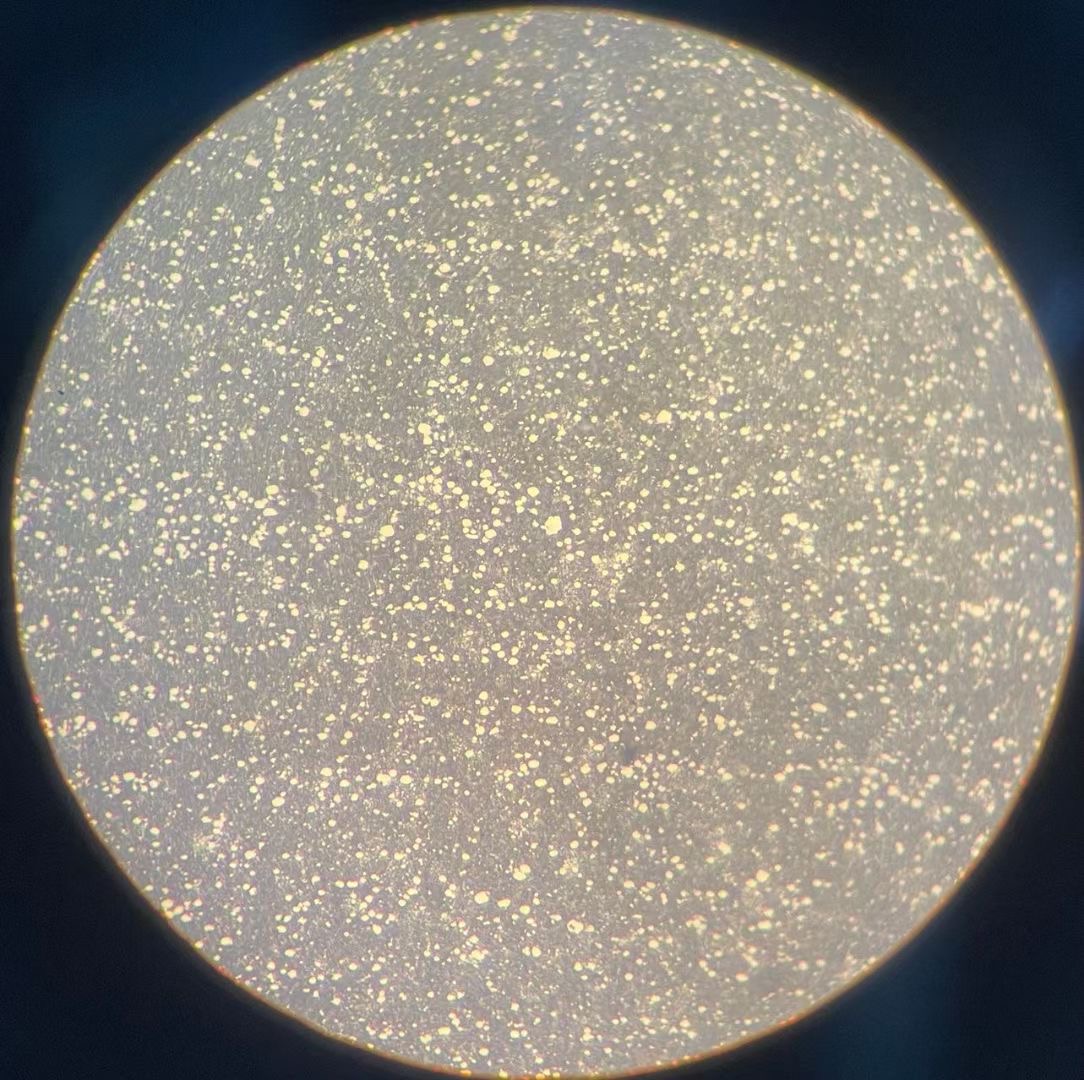

Vacuum Degassing & Rapid Solidification:

guarantees homogeneous microstructure, minimized impurities, and optimized carbide distribution for consistent performance and durability.

Customized Precision Heat Treatment:

Customized processes improve mechanical strength and provide reliability over very rough industrial surroundings.

Cost Savings ZDF-T1016 High Speed Steel Tools have a service life more than 50% greater than conventional ones. This not only minimizes the frequency of tool replacement, but also minimizes downtime, ultimately resulting in enhanced productivity and cost savings for your operations.

We offer customized solutions to meet your specific needs, whether you require precision round bars, cold-drawn wires, or specialized cutting tools. Our team works closely with you to develop products that align with your performance requirements and application demands.

With over a decade of experience producing high-speed steel, we use technologies that have never been employed by other manufacturers along with proprietary heat treat processes to create a product that is simply better than anything else on the market. ZDF-T1016 has been widely trusted by manufacturers from all over the world for its reliability, performance, and versatility.

ZDF-T1016 High Speed Steel can be used for many industrial applications, such as:

Cutting Tools: Taps, drills, end mills and reamers

Punching Tools: Hardness tensile punch bars and precision punches.

Saw Blades: Band saw blades for slicing tough material.

Precision Components: High-performance parts requiring wear resistance and durability.

What types of T1016 high speed steel do you offer?

We are a raw material supplier that provides ZDF-T1016 in different forms such as round bars, plates, strips and forged blanks and also making semi-finished or finished products such as taps or drills.

Is it all-in-one service from raw material to final products?

Yes, we provide a one-stop solution from T1016 high-speed steel raw material supply to finished product processing service including forging, machining, and heat treatment. By doing this, products satisfy customer demand and production efficiency is maximized.

What is the delivery time T1016 high-speed steel?

We own the entire production process from raw material to finished product which makes us able to deliver at a faster speed than market average. Lead time will vary based on the size of the order and processing requirements.

Do you accept customer-defined T1016 high-speed steel?

Yes, we support customized production and can tailor the size, shape, and mechanical properties of T1016 high-speed steel to meet different application requirements.