Our company made one specialized steel-ZDF-P20, which can replace M42 for high toughness. Not only does this replace dramatically improve service life and performance — it also cuts costs.

Additionally, ZDF-P20 compensates for the lack of strength in M35, making it a cost-effective solution for a variety of applications.

| C | W | Mo | Cr | V | Co |

|---|---|---|---|---|---|

| 0.95-1.00 | 6.00-6.50 | 4.90-5.20 | 4.00-4.40 | 2.00-2.10 | 8.00-8.20 |

| Type | Specification(mm) | Surface condition |

| Hot-rolled Round Bar | Φ10.5-φ65 | Ground/Turned |

| Cold-drawn Steel Wire | Φ2.0-φ13.5 | Ground/Polished/Black |

| Band saw blade wire | 1.13*1.4 etc. | No decarbonization |

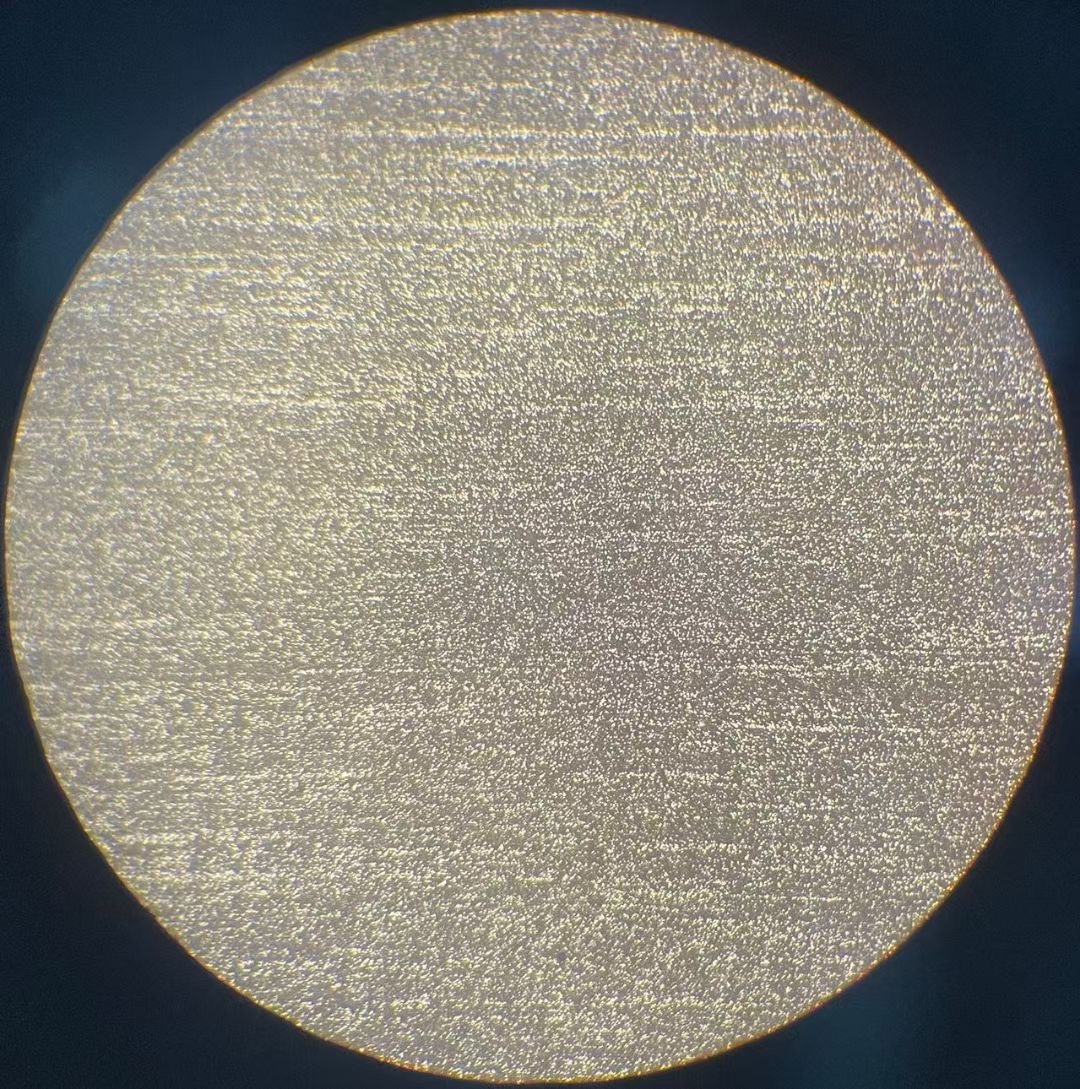

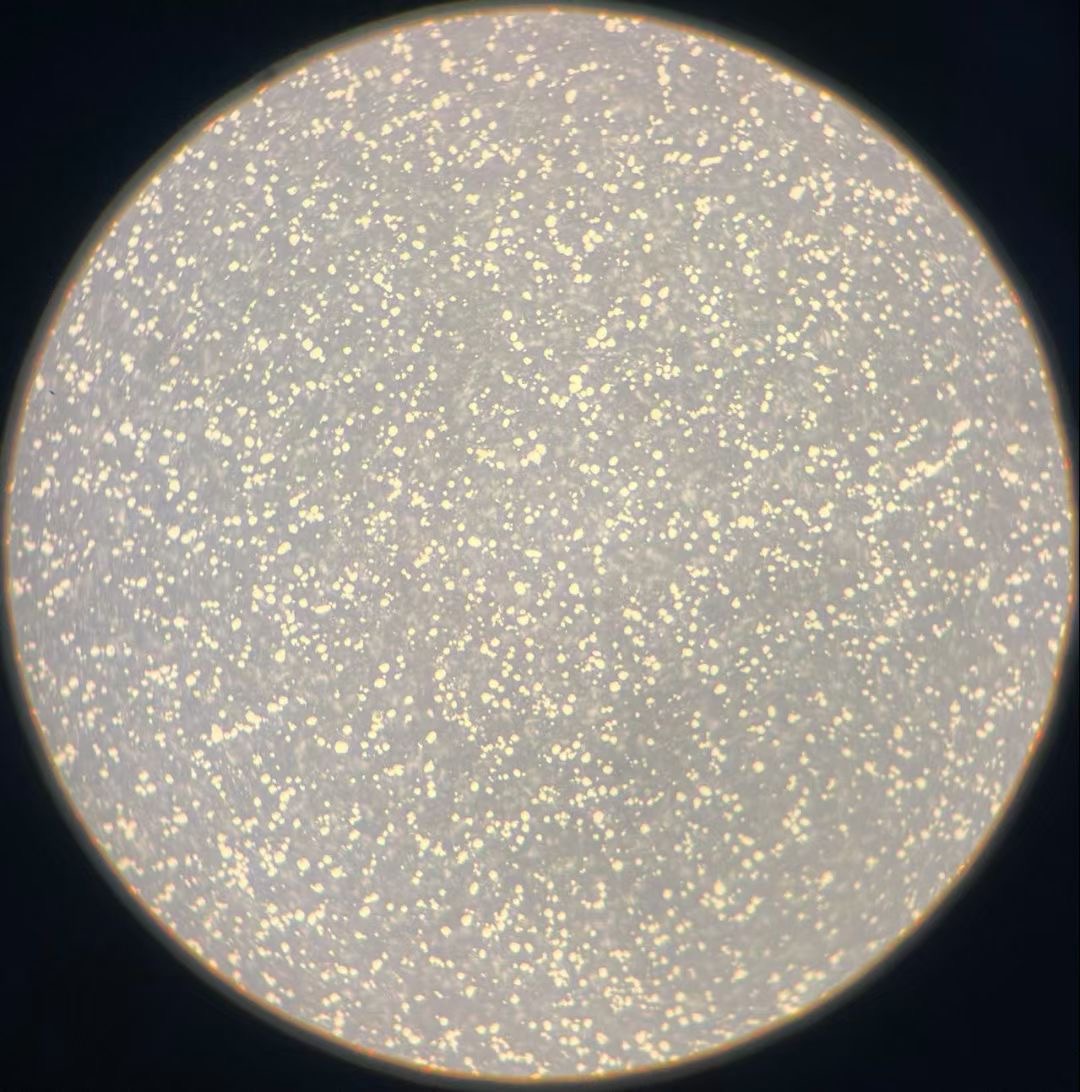

ZDF-P20 is produced with our company original “Directional Process” technology. Carbide particles in steel are fine and written in a uniform distribution & offer better properties than M35 & M42. This makes it a perfect alternative for powder metallurgy products.

After heat treatment, ZDF-P20 exhibits excellent all-around properties, making it a top choice for mold manufacturing:

Wear Resistance: Top wear resistance; makes the life of the steel longer.

Outstanding Durability & Crack Resistance: High stress resistance dramatically reduces crack possibility.

Super High Machining Performance: Easy processing and polishing, suitable for high-precision steel manufacturing.

Bang for your buck: Offers high-end performance at lower prices.

Coherent Products at Competitive Prices

You are Unique, and Our ZDF-P20 steel is as good as international brands like Japan, Europe & USA, but in a very economic cost.

Advanced Manufacturing

Employing the entire metallurgical process chain EAF + LF + VD + ESR, we guarantee a homogenous microstructure, fine dispersion of carbides and high toughness.

Quality Control

Our ZDF-P20 steel is delivered with guaranteed precision and in compliance with international standards (GB, AISI, JIS, DIN) and, of course, customer requirements.

Diffusion Hardening

Our leading diffusion hardening technology maximizes hardness, wear resistance and polishability.

Custom Solutions

We can customize a construction with the width, shape and hardness for your specific application.

HSS P20 commonly used all over the industry as a combination of excellent hardness, wear resistance and toughness. Common applications include:

Cutting Tools: Excellent hardness and edge retaining properties make Tungsten a very popular choice for producing drill bits, taps, punch and reamers.

Cold Work Dies: These are used for high wear applications like punching, stamping, and blanking dies.

Automotive Components: Excellent for producing custom parts like high-performance gears and shafts.

Industrial blades: Commonly used incutting tools can be found in the woodworking, metalworking, and plastic industries.

Precision Engineering: Used in high-speed machining tools and other harsh applications

Are HSS P20 specifications available to be met as per customer’s requirements?

Yes, we have full degree of customization including transverse properties, number of hardness levels, shape as per customer requirements etc

What maintenance is required for HSS P20 tools?

Inspection on a regular basis, greasing properly and regrinding is done to function efficiently. Managing temperature and cooling methods greatly increase tool life.

What services do you provide?

With raw material supply, precision machined parts, heat treatment, short delivery times and tool optimization.

How do you validate HSS P20 quality?

We ensure the quality of our products through factitious quality control, chemical composition, hardness, and metallographic analysis, which we perform at all stages of production.

We are a well-known ZDF-P20 tool steel supplier and can provide plate, round bar, and flat steel.

We provide the best quality P20 special tool steel with guaranteed quality assurance and trusted service. Our competitive pricing and reliable supply chain support your production needs and cost-efficiency.