Alloyed with balanced levels of carbon, vanadium, molybdenum, and cobalt, PM30 / 1.3294 offers an excellent combination of wear resistance and toughness.

Commonly known as ASP2030, this spray forming powder metallurgy high-speed steel provides superior edge retention and thermal stability under demanding cutting conditions. The advanced spray forming process ensures a uniform, fine microstructure with evenly distributed carbides, resulting in high dimensional stability and extended tool life.

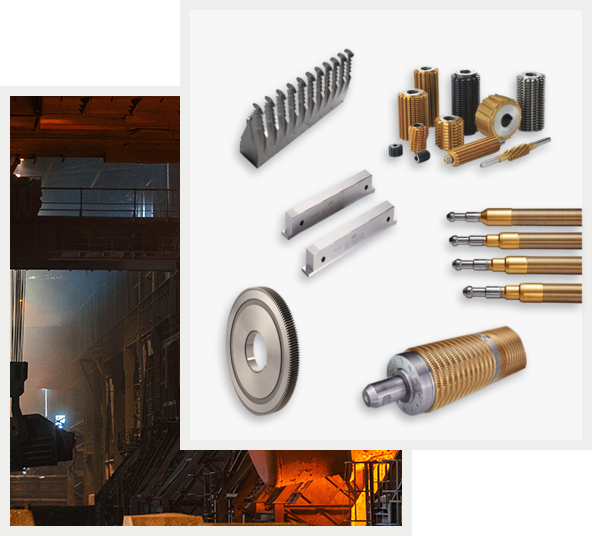

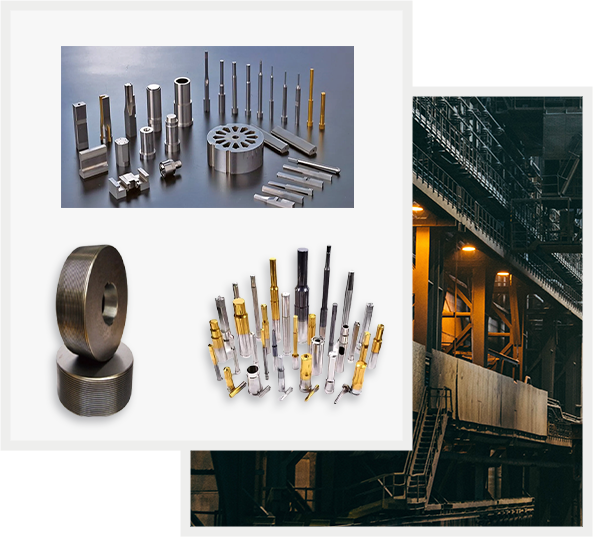

PM30 is especially suitable for high-performance cutting tools, broaches, end mills, reamers, and punches that require a balance of toughness and wear resistance under both thermal and mechanical load.

| ZEICIN Grade | GB | AISI | DIN | JIS | Erasteel | Bohler | Hitachi |

| P30 | *CW6Mo5Cr4V3Co8 | P30 | 1.3294 | SKH56 | ASP2030 | S590 | HAP40 |

| C | W | Mo | Cr | V | Co | Al | Mn | Si | S | P |

|---|---|---|---|---|---|---|---|---|---|---|

| 1.28 | 6.50 | 4.90 | 4.00 | 2.90 | 8.30 | – | 0.30 | 0.40 | ≤0.015 | ≤0.030 |

1. Annealing

Slowly heat the steel to 850-900°C and hold for 2-4 hours. Then allow the furnace to cool below 600°C, followed by air cooling.

This process results in an annealed hardness of ≤ 280 HB, ensuring good machinability before hardening.

2. Hardening (Quenching)

Preheat in stages:

First to 450-500°C

Then to 850-900°C

Finally, heat to the austenitizing temperature of 1180-1200°C, with appropriate holding time based on cross-sectional thickness.

Rapid quenching in oil, salt bath, or vacuum gas is recommended to achieve a fine, uniform microstructure and optimal hardness.

3. Tempering

Tempering should be done immediately after quenching to relieve internal stresses and enhance toughness and dimensional stability.

The recommended tempering temperature range is 540-600°C. For best performance, double or triple tempering is recommended.

After tempering, the hardness typically reaches 65-68 HRC, depending on section size and process control.

| Item | Value |

| Annealed Hardness | 280HB |

| Hardening Temperature | 1180ºC – 1200 ºC |

| Tempering Temperature | 540ºC – 600ºC |

| Tempered Hardness | 65 – 68 HRC |

Exceptional Value for Money

1. Superior Toughness and Wear Resistance at a Competitive Price

PM30 / 1.3294 (also known as ASP2030) is engineered for tooling applications that demand both high toughness and excellent wear resistance. It delivers comparable or superior performance to leading international brands, but with greater cost-efficiency. This makes it an ideal choice for manufacturers seeking reliability without excessive material costs.

2. Good Machinability in Annealed Condition

With controlled annealing to ≤280 HB, PM30 ensures easy machinability before heat treatment, reducing tool fabrication time and wear on equipment.

Advanced Manufacturing Technology

1. Spray Forming Powder Metallurgy Process

Produced using advanced spray forming technology, PM30 features a highly uniform and fine carbide distribution with minimal segregation. This results in improved mechanical properties, superior wear resistance, and increased process stability under heavy-duty operations.

2. Optimised Heat Treatment

With hardening temperatures of 1180-1200°C and tempering at 540-600°C, PM30 achieves hardness levels of 65-68 HRC. This ensures strong resistance to deformation, excellent cutting-edge durability, and a long tool life even under extreme working conditions.

Reliable Product Quality

1. Full-Process Quality Management

From powder selection through final inspection, our strict quality control system ensures stable mechanical properties and dimensional precision across all batches.

2. International Standards Compliance

PM30 / 1.3294 conforms to major global standards such as ASTM, DIN, JIS, and GB, ensuring broad acceptance and reliability across different tooling industries.

Technical Innovation and Expertise

1. Continuous Development and Innovation

Supported by ongoing R&D investment, we continuously improve our powder metallurgy and spray forming technologies to meet the evolving needs of high-performance tool steel users.

2. Collaboration with Top Institutions

We work with leading universities and metallurgical research institutes to enhance steel purity, control carbide structure, and extend tool performance through advanced heat treatment techniques.

3. Tailored Solutions for Demanding Applications

Our spray forming platform allows for property customisation of PM30 to meet specific performance demands in broaches, gear cutters, milling tools, cold working punches, and wear-resistant tooling.

PM30 / 1.3294 Spray Forming Powder Metallurgy High-Speed Steel (also known as ASP2030) is designed for cutting and forming tools that require a high level of wear resistance and toughness. Its balanced alloy composition and refined microstructure make it particularly effective in high-load, high-cycle applications.

Typical Applications Include:

Machine Taps – Ideal for threading tough materials with high tool life and edge retention.

General Cutting Tools – Such as end mills, drills, reamers, and countersinks used in high-speed or continuous cutting operations.

Punches and Cold Work Tools – Suitable for cold forming and blanking, where both wear resistance and impact strength are required.

Knives and Shear Blades – For industrial cutting of metal, plastics, and composite materials.

Gear Cutting Tools – Hobs and shaping cutters require consistent hardness and accuracy under continuous use.

Industries Served:

Machinery, Automotive, General Engineering, Molds & Dies, and Metalworking.

PM30 / 1.3294 (also known as ASP2030) is a high-performance powder metallurgy high-speed steel known for its excellent wear resistance, good toughness, and fine, uniform carbide structure. Manufactured using advanced spray forming technology, it offers better performance and stability than conventional grades like M2 or M3:2, especially in demanding cutting and cold work applications.

Thanks to the spray forming process, PM30 has:

High wear resistance for long tool life

Good toughness to resist chipping and cracking

Uniform microstructure that improves dimensional stability

These properties make it highly reliable in continuous, high-load operations.

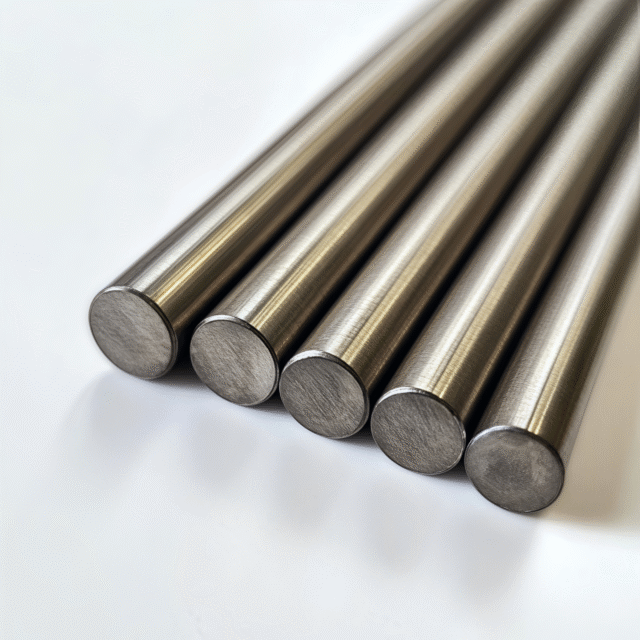

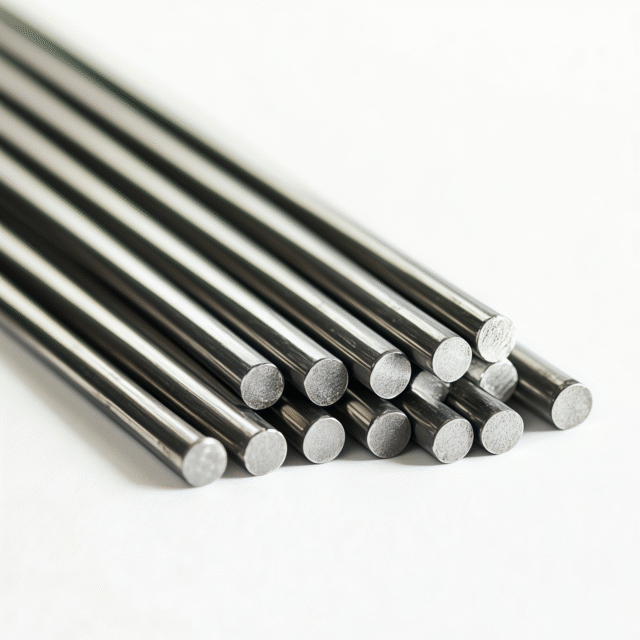

Yes. We offer customized dimensions based on your needs. Common supply forms include:

Round bars

Flat bars

Square bars

Near-net profiles

Surface conditions like turned, ground, cold drawn, or polished are also available.

PM30 products can be supplied with:

Grinding

Polishing

Black oxide coating

Other custom finishes

These treatments improve surface quality and tool performance.