Our innovation and technical advantage is the M35+V, which is the most competitive selling point of our HSS product by what extent we improved the service life and performance of HSS tools compared to the maximum performance of M35.

M35+V Base on M35 to be used our unique technology EAF+LF+VD+RS ESR process enable to make V Maximum 2.5 to gain wear resistance so as to improve work life.

| Execution Standard | ZEICIN Grade | GB | AISI | JIS | DIN |

|---|---|---|---|---|---|

| GB/T9943-2008 | M35+V | M35+V |

| C | W | Mo | Cr | V | Co | Al | Mn | Si | S | P |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.87~0.95 | 5.90~6.70 | 4.70~5.20 | 3.80~4.50 | 2.40~2.50 | 4.50-5.50 | - | 0.15-0.40 | 0.25-0.45 | ≤0.03 | ≤0.03 |

| Type | Specification(mm) | Surface Condition |

|---|---|---|

| Cold-drawn Round Steel | φ2-10 | Black |

| Hot-rolled Round Steel | φ11-75 | Turned |

| Precision Forging Round Steel | φ80-120 | Turned |

| TW | 20 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|

| 3 | √ | √ | √ | √ | ||||||

| 4~5 | √ | √ | √ | √ | √ | √ | ||||

| 6~13 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 14 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 15~18 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 19 | √ | √ | √ | √ | √ | √ | √ | |||

| 20 | √ | √ | √ | √ | √ | √ | √ | √ |

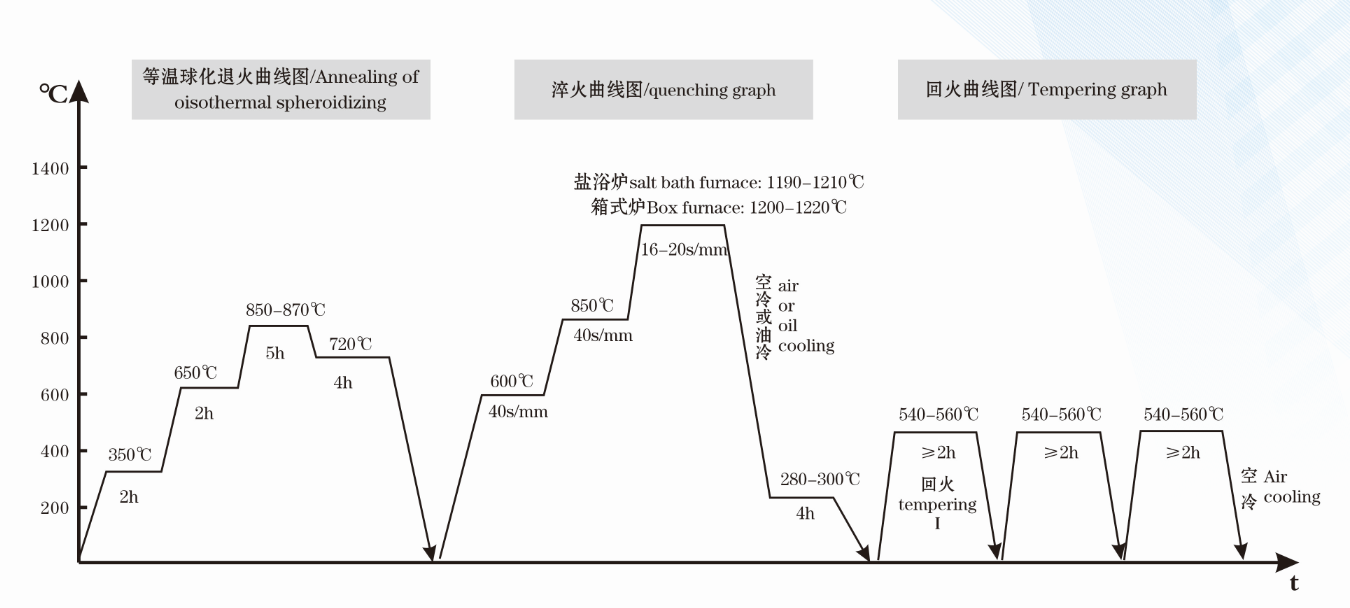

In addition, the M35+V heat treatment plays a significant role in maximizing hardness, wear resistance, and toughness. The process includes three main steps:

Annealing: Steel is softened, internal stress relieved and machinability improved.

Quenched: Allows for a hardened state that improves wear resistance.

Tempering: Relieves quenching stresses, control hardness, increase toughness.

Annealing: 350℃/2h → 650℃/2h → 850–870℃/5h → 720℃/4h

Quenching:

Salt Bath Furnace: 1190-1210℃

Box Furnace: 1200-1220℃

Air or oil cooling

Tempering: 540 ~ 560℃ ≥ 2h (3 times repeat)

High Hardness: HRC 63-65 Excellent red hardness and wear resistance

High speed cutting applications: Good wear resistance.

Improved Toughness: Retains excellent resistance to impact and flexural strength.

Prevents Surface Oxidation and Corrosion:Regular application of anti-rust oil.

Regular Reheat Treatment:Fix performance periodically.

Proven Toughness: This High-Speed steel retains the cutting edge stability in the high-stress condition, hence, Providing a longtime usage even on the tough applications.

High Hardness & Red Hardness: High HRC (63-65), if red hardness is wonderful, suitable for high speed cutting operation in aviation and tool manufacturing.

Precision Machining: With its fine & uniform carbide distribution, it’s ideal for precision components, and jobs that require tight tolerances.

Higher Wear Resistance and Toughness

Vanadium Content: optimized for wear-resistance higher than standard M35.

High Toughness: Stays stable of cutting edge in high-stressed conditions.

Technologies for Advanced Production

Precision Heat Treatment: Provides optimum hardness & red hardness for demanding applications.

Precision Heat Treatment: Provides optimum hardness & red hardness for demanding applications.

Quality You Can Count On

Industry-Recognized Specification:Meets or exceeds GB, AISI, JIS, and DIN specifications.

M35+V is tested in every batch to guarantee its quality standards.

Tailored Solutions for High-Performance Applications

Special Processing: Bars, flats and finished components per customer specification.

Whether you need bars, flats, or fully processed components,we offer tailored solutions to fit your needs. Our product range includes different sizes and surface conditions (hot-rolled, cold-drawn, precision forged).

M35+V Can be used for a variety of manufacturing and processing of hard cutting tools, Improved tool life with greater performance over the M35,such as gear cutter, milling cutter, punch ,taps, drill, etc.

Cutting tools: precision components, drill bits, turning tools, taps and dies.

Press/Tooling: Pinch, die, and gear slicing tools

Geothermal Machining: Aerospace, automotive and die manufacture.

Use cases: Specialized applications (medical instruments, precision components).

What is different about your M35+V high-speed steel?

We are a professional raw material manufacturer of high-speed steel. The premium M35+V high-speed steel sits unlike any others with quality materials, optimized chemical composition, and state-of-the-art manufacturing processes. This guarantees great wear resistance, toughness, and machining versatility.

Do you offer tailored M35+V products?

Yes! We supply the best raw material steel, providing cutting and processing at an exacting standard. Your requirements can be satisfied with the supply of semi-finished parts or fully finished parts.

Do you have one-stop service about high speed steel?

Absolutely. We offer an integrated supply chain, providing raw material supply, precision cutting, machining, and finished product manufacturing. This allows for a more smooth process, faster shipping, and cheaper rates.

How do I obtain a quote or further technical specifications?

Contact us by email zeicin@zeicin.com