M2 high-speed steel features excellent hardness (62-64 HRC) and superior wear resistance. It performs reliably under high temperatures, shock, and vibration, extending tool life.

Ordinary HSS often suffers from edge chipping and short tool life during frequent or continuous cutting. M2 steel, with more uniform carbide distribution and higher toughness, improves cutting stability, reduces tool changes, and lowers overall cost.

| Execution Standard | ZEICIN Grade | GB | AISI | JIS | DIN |

|---|---|---|---|---|---|

| GB/T9943-2008 | M2RE | W6Mo5Cr4V2 | M2 | SKH51 | 1.3343 |

| C | W | Mo | Cr | V | Co | Al | Mn | Si | S | P |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.80-0.90 | 5.50-6.75 | 4.50-5.50 | 3.80-4.40 | 1.75-2.20 | – | – | 0.15-0.40 | 0.20-0.45 | ≤0.03 | ≤0.03 |

| Type | Specification(mm) | Surface Condition |

|---|---|---|

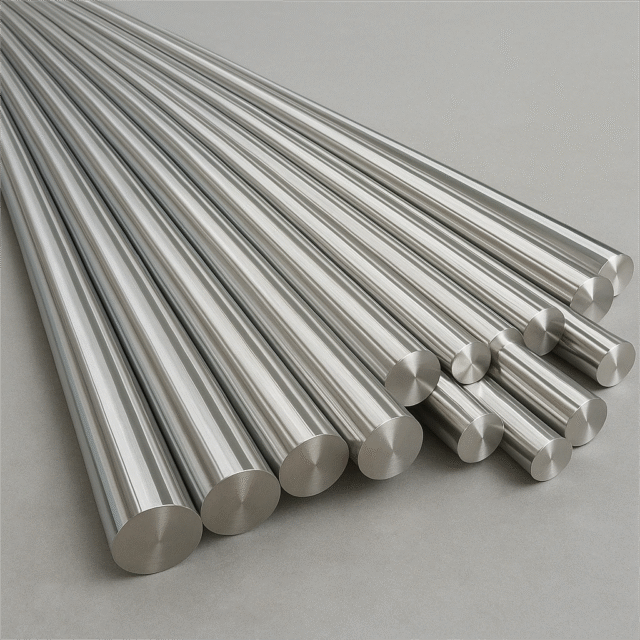

| Cold-drawn Round Steel | φ2-10 | Black |

| Hot-rolled Round Steel | φ11-75 | Turned |

| Precision Forging Round Steel | φ80-120 | Turned |

| TW | 20 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|

| 3 | √ | √ | √ | √ | ||||||

| 4~5 | √ | √ | √ | √ | √ | √ | ||||

| 6~13 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 14 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 15~18 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 19 | √ | √ | √ | √ | √ | √ | √ | |||

| 20 | √ | √ | √ | √ | √ | √ | √ | √ |

Hardening and tempering of M2 high-speed steel have played an important role in improving its hardness, wear resistance. and toughness. The typical heat treatment for M2 high-speed steel generally follows an Anneal, Quench, and Temper process scheme. Here is the detailed explanation for each step:

Basically, to softens the steel by relieving stress and making it easier to machine.

A process of heat treatment to increase hardness and wear resistance by rapidly cooling the steel.

When using M2 steel, tempering follows quenching in order to relieve stress and fine-tune hardness and toughness for optimum performance.

The following properties can be obtained after proper heat treatment on M2 high-speed steel:

Very Strong Hardness:

Hardness 62-64 HRC, Shape cutting tasks.

Fantastic Wear Resistance:

The quenching and tempering process puts them in a condensed matrix, very suitable for high-frequency and long-term cutting.

The tempering process eliminates internal stress, increases impact resistance for complex machining and heavy-duty applications.

1. Excellent Hot Hardness and Wear Resistance

1.3343 (M2 / SKH51) high speed steel rod offers outstanding hot hardness and wear resistance, making it an ideal material for high-speed cutting tools and demanding machining operations. The optimized alloy composition ensures reliable cutting performance and extended tool life under elevated temperatures.

2. Reliable Toughness and Stable Cutting Performance

With a well-balanced combination of toughness and hardness, M2 / SKH51 high speed steel effectively reduces the risk of edge chipping and premature failure. This stability makes it suitable for continuous cutting and heavy-duty applications.

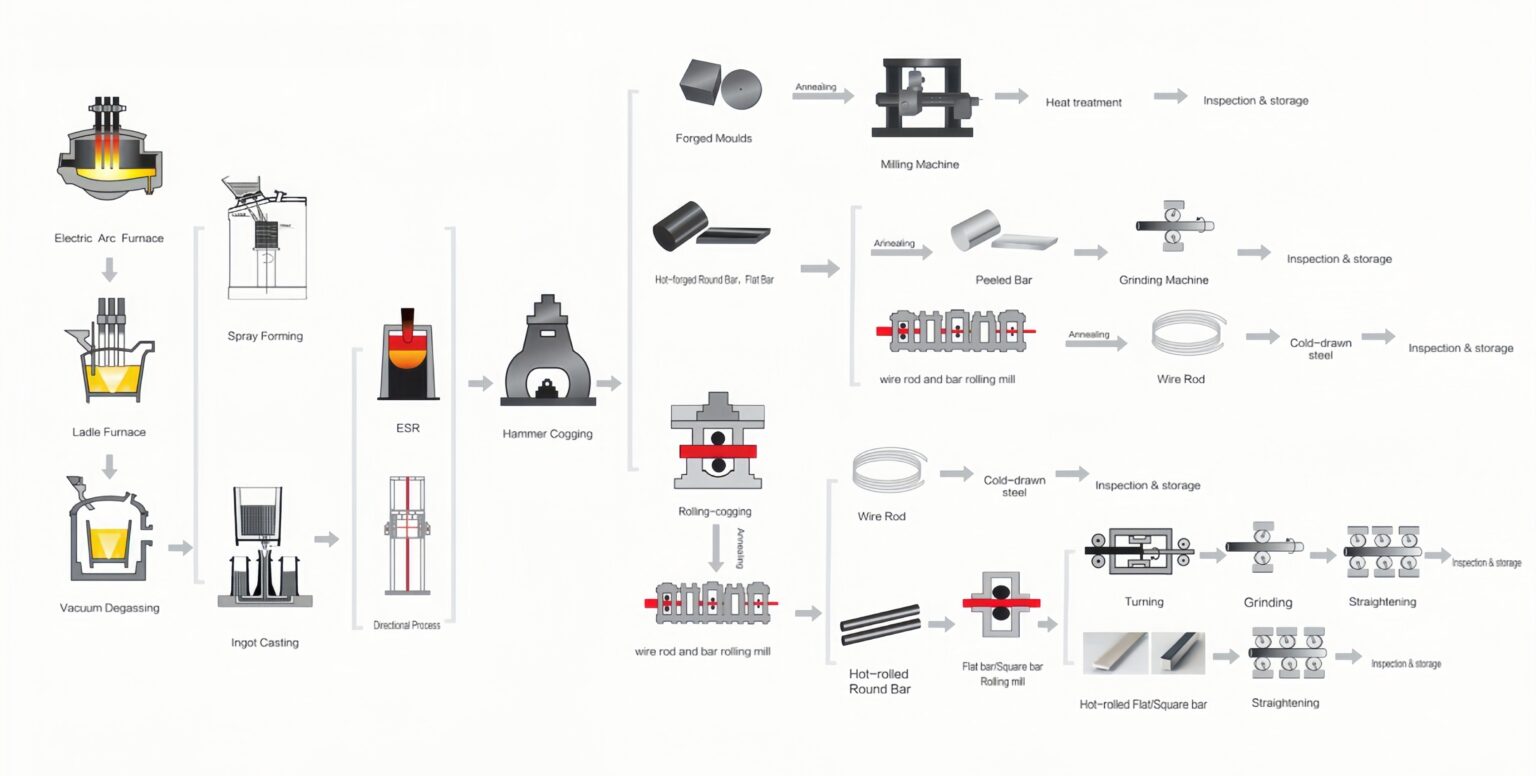

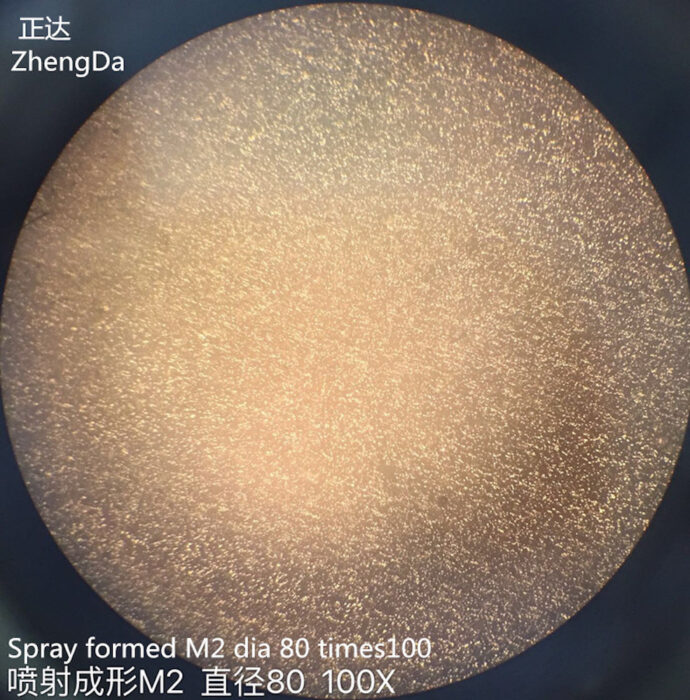

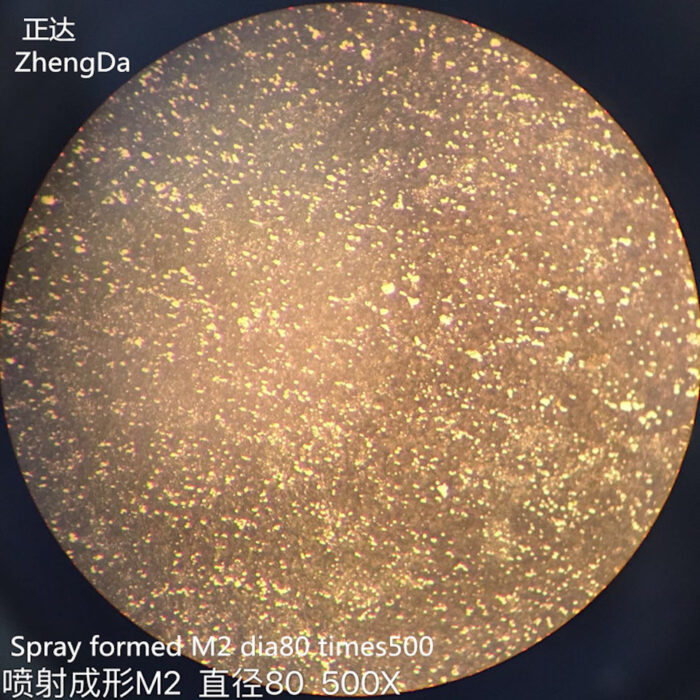

1. Mature High-Speed Steel Production Process

1.3343 high speed steel rods are manufactured using a proven and mature high-speed steel production process. This ensures a uniform microstructure and fine, evenly distributed carbides, providing consistent mechanical properties throughout the material.

2. Reliable Heat Treatment Performance

After proper heat treatment, M2 / SKH51 high speed steel achieves high hardness, excellent thermal stability, and strong resistance to softening at elevated temperatures, ensuring long service life in high-speed and high-load cutting conditions.

1. Stable Quality Control

Strict quality control and inspection procedures are applied at every production stage to guarantee consistent hardness, strength, and performance across different batches of 1.3343 high speed steel rods.

2. International Standards Compliance

M2 / SKH51 (1.3343) high speed steel complies with major international standards such as ASTM, DIN, JIS, and GB, and is widely recognized and used in the global cutting tool and tooling industry.

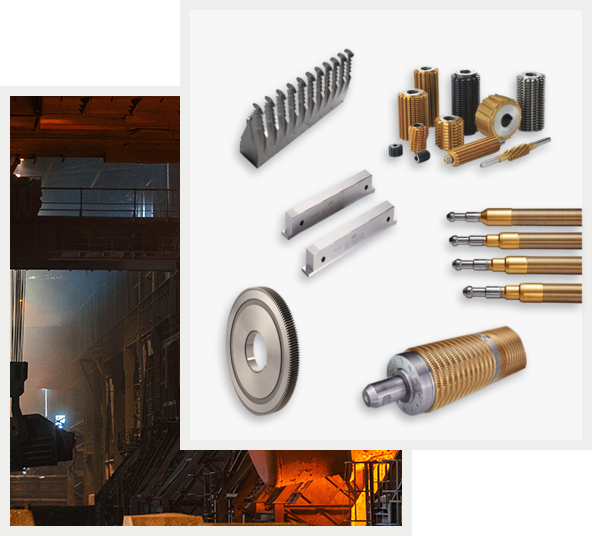

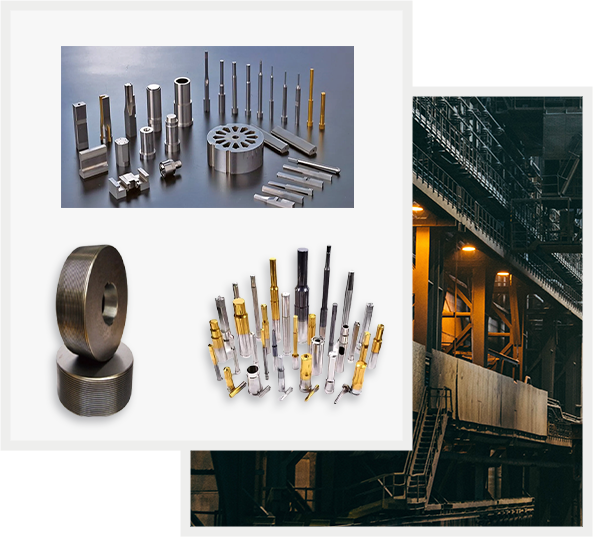

Applicable to the production of drill, tap, screw die, milling cutter, gear cutter, cold die mold, and other cutting tools, and molds with high wear resistance and strength.

Heavy-Duty Molds

For punch dies, cold extrusion dies, and forming molds under heavy loads and high-wear conditions.

Q1: Do you accept trial orders?

A1: Yes, we accept trial orders, provided that the required size and model are in stock.

Q2: What is your delivery time?

A2: If the products are in stock, the delivery time is generally 5-15 days. If the products are out of stock, the delivery time may range from 15 to 20 days, depending on the order quantity.

Q3: Do you offer discounts for bulk orders?

A3: Yes, we offer discounts for bulk orders. The specific discount will depend on the order quantity and the terms of cooperation. Please do not hesitate to contact us for more information.

Q4: What is your product packaging like?

A4: Our products are packaged in standard industrial packaging to ensure safety during transportation. If you have specific packaging requirements, please let us know when placing the order, and we will package your items accordingly.

Q5: What payment methods do you support?

A5: We accept a variety of payment methods, including T/T, L/C, Alipay, PayPal, etc. The specific payment method can be arranged flexibly based on the order amount and customer needs.