Our common international payment methods include T/T and L/C. For trade terms, we can also support options such as DDU based on the order. The final payment method and terms can be confirmed according to your country/region, order value, and delivery method.

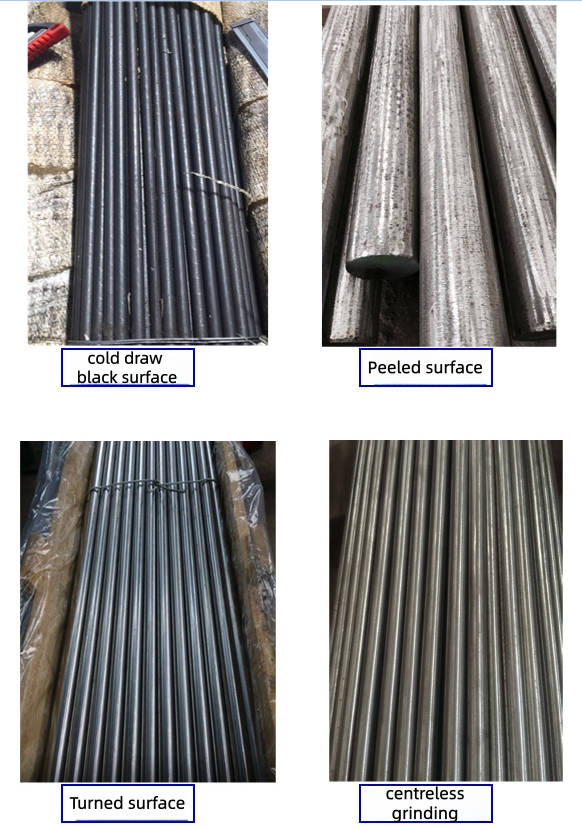

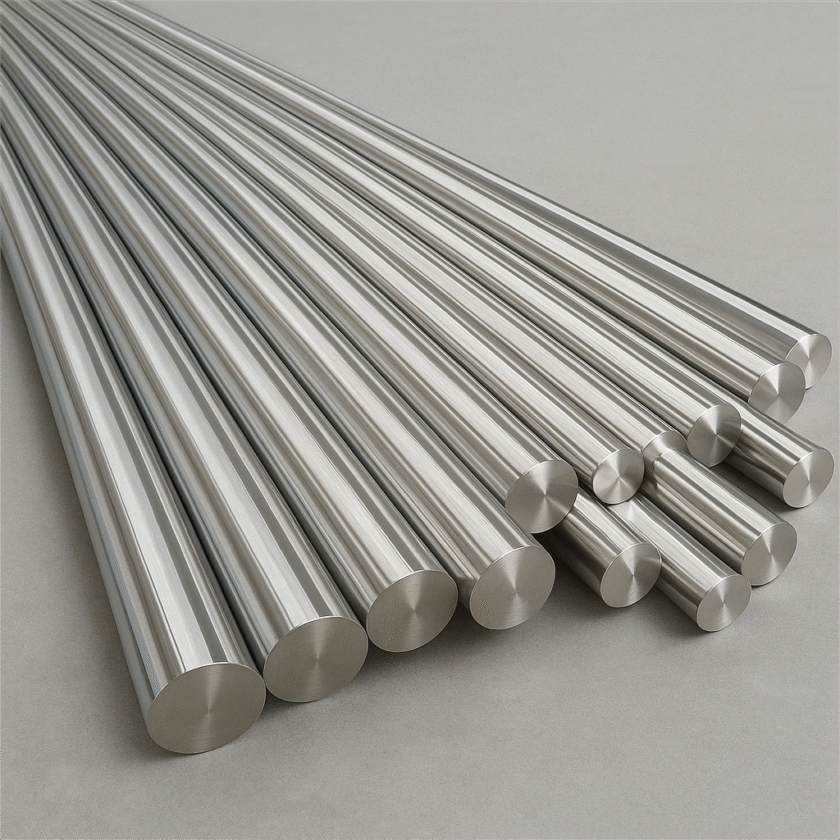

Surface Condition Gallery

Different surface conditions affect appearance, dimensional accuracy, and machining allowance. The images below show common delivery options (actual products may vary by size and batch).