High-speed steel (HSS) is an important material for cutting tools, and in particular, taps. P30 steel is one of many HSS grades that offer excellent wearing properties, grindability, and has become a steel of choice. Typical HSS (high-speed steel) grades like P30 experience significant carbide segregation and coarse carbide particles during casting, making it difficult for the material to achieve optimal performance.

At present, the HSS production processes are mainly divided into three types: conventional casting, injection molding, and powder metallurgy. In these respects, HSS with more than 3% vanadium is generally considered unsuitable for traditional casting because of the inability to control its carbide structures.

However, we have significantly improved the quality of P30 steel by applying a technique known as Directional Electroslag Remelting (Directional ESR) to the traditionally smelted and die-cast HSS billets, combined with billet processing using a thousand-ton hydraulic press.

This innovative process, while maintaining the same chemical composition as Erasteel ASP2030, significantly enhances the carbide distribution in high-vanadium, high-cobalt HSS and refines carbide particle size, effectively overcoming the inherent drawbacks of traditional methods.

This optimized P30 shows good wear resistance, and better grindability makes it an ideal material for tap manufacturing.

The segregation and coarsening of carbides is the key problem in the traditional casting of high-vanadium high-speed steel (e.g., P30 steel). In this regard, we have taken the following optimization measures to resolve it:

Directional Electroslag Remelting (ESR) Technology:

ESR helps to eliminate inclusions in molten steel, resulting in purer steel. Also, due to directional solidification in the ESR process, carbide size is refined and carbide segregation is reduced [6]. In particular, the ESR process is capable of controlling the molten pool appearance and the cooling rate to guarantee a homogenous carbide distribution on solidification, leading to microstructure properties which greatly improve the material microstructure.

Forging with a Thousand-Ton Hydraulic Press:

With ESR done, a thousand-ton hydraulic press performs the first stage of the forging process, refining the grain structure and distributing carbides. Forging applies plastic deformation, leading to coarse carbide fracture, which leads to smaller carbide size and homogeneous dispersion.

The powder metallurgy technique (see, e.g., the manufacture of ASP2030 steel) provides substantial advantages in high-performance high-speed steels in the following key areas:

Uniform Distribution of Carbides:

Carbides like TiC show uniform distribution in the matrix, by powder metallurgy technique, by rapid solidification technology to prepare fine powder, and consolidated by hot isostatic pressing (HIP). The process helps overcome carbide segregation problems associated with conventional casting, resulting in carbide being less than 3µm and uniform.

Production of High-Performance Materials:

Compared with conventional processing technology, powder metallurgy is especially applicable to the production of high vanadium, high cobalt, and other high-alloy high-speed steel, improving hardness, wear resistance, and toughness. For instance, the carbide in ASP2030 steel has a size of 3µm, which, unlike the 10µm found in P30 steels that are traditionally cast, is considered very small.

Capability to Form Complex Shapes:

Powder metallurgy enables the manufacturing of tools with complex geometry (milling cutters, drills, etc.), thus offering a higher design flexibility.

Traditional casting, powder metallurgy, and injection molding processes differ in terms of production costs, equipment requirements, and manufacturing efficiency:

Traditional Casting Process:

Conventional Casting Process is characterized by low equipment investment, large-scale production, but carbide control is difficult. This requires further processes of forging and heat treatment, thus more cost overall.

Powder Metallurgy Process:

Capital equipment is generally quite high, especially hot isostatic pressing (HIP) and rapid solidification equipment, but it improves the properties of the materials a lot, which is perfect for high-value-added products. Although it is more expensive to manufacture, the performance benefits are considerable.

Injection Molding Process:

Best for medium production of small, intricate shape components. Despite extensive equipment and material costs, this process could achieve great production efficiency and is therefore most suitable for batch production of small cutting tools.

| Process Type | Equipment Cost | Production Efficiency | Carbide Control Ability | Application Scenarios |

| Traditional Casting | Low | High | Average | Large-scale production, low-cost requirements |

| Powder Metallurgy | High | Medium | Excellent | High-performance, high-value-added products |

| Injection Molding | Medium | High | Good | Small,complex-shaped components |

The chemical composition (wt%) of traditional P30 steel and powder steel 2030 is as follows:

| Grade | Chemical Composition | ||||||||

| C | S | W | Mo | Cr | V | Co | O | N | |

| P30 | 1.22 | 0.004 | 6.78 | 5.40 | 4.12 | 3.06 | 7.42 | 0.0027 | 0.020 |

| HOP2030 | 1.29 | 0.004 | 6.27 | 4.90 | 4.06 | 3.12 | 8.4 | 0.0064 | 0.031 |

| ASP2030 | 1.27 | 0.004 | 6.54 | 5.25 | 3.99 | 3.24 | 8.57 | 0.0018 | 0.065 |

Comparison:

P30 steel has lower Co content and higher W and Mo contents compared to powder high-speed steel 2030.

.png)

.png)

.png)

.png)

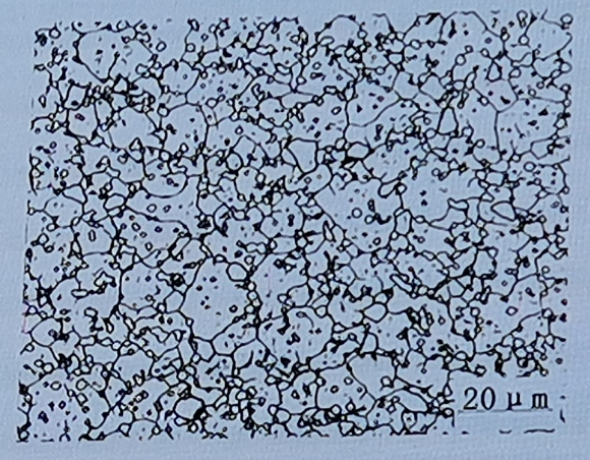

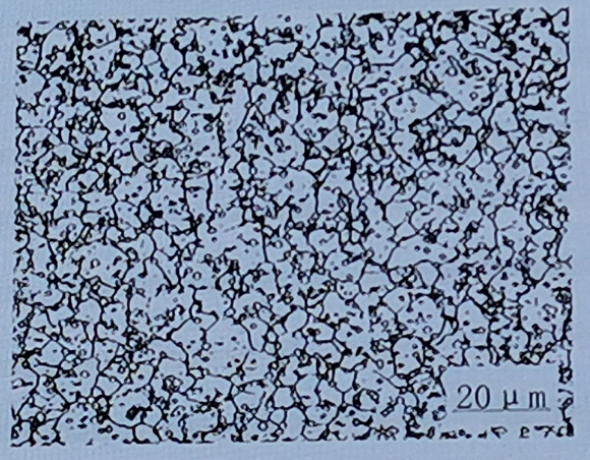

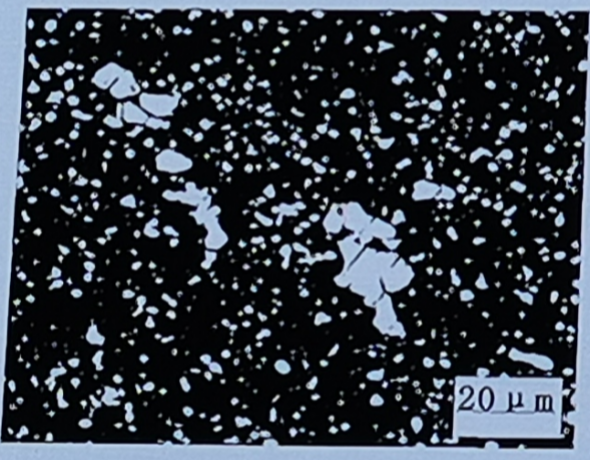

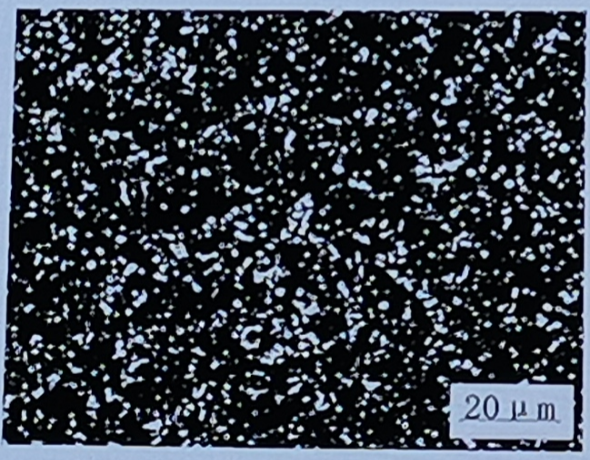

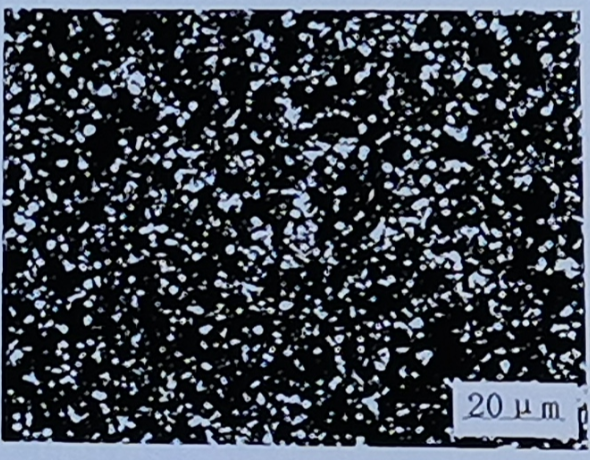

Figure 1: Microstructure of P30 Steel and 2030 Steel

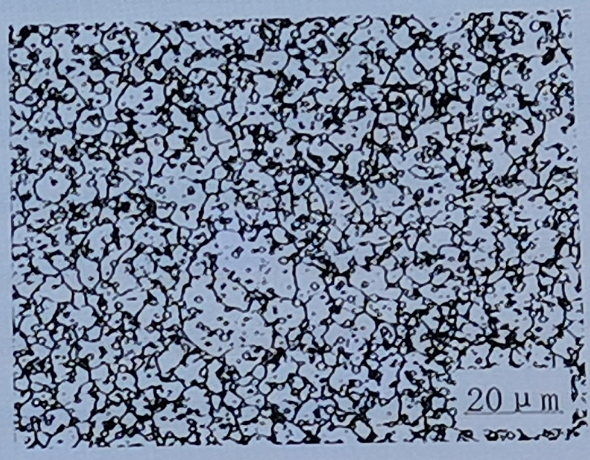

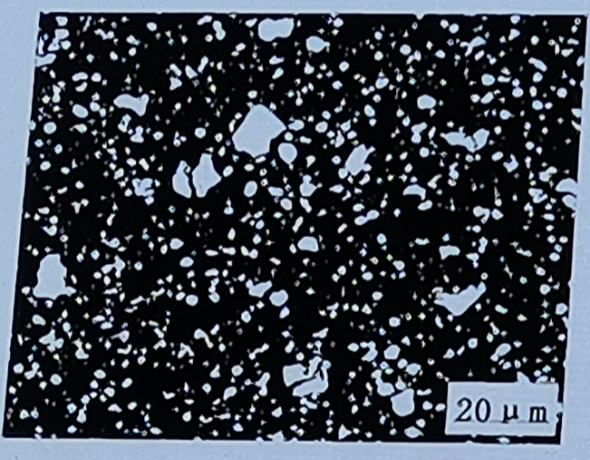

Figure 2: Quenching Microstructure of P30 Steel and 2030 Steel

Compare the three:

① The quenching grain of P30 steel is 10.5#, which is large;

② There is no obvious difference between HOP2030 steel and ASP2030 steel, both of which are 12# and fine.

Figure 3: Tempering Microstructure of P30 Steel and 2030 Steel

At the quenching temperature, P30 steel and powder 2030 steel are not overheated

Table 3: Tempering Hardness (HRC) of P30 Steel and 2030 Steel

| Grade | Tempering Hardness (HRC) |

| P30 | 66.9 |

| HOP2030 | 67.1 |

| ASP2030 | 67.1 |

There is no significant difference in tempering hardness under the same quenching and tempering processes.

The grinding process for taps made from all three materials is identical. In the groove grinding sequence, P30 steel is harder to grind than HOP2030 and ASP2030 steels, with slight darkening of the cutting edges.

P30 steel, being a traditional cast high-vanadium steel, is affected by the nitrogen content in the molten steel, which influences the morphology and size of primary eutectic carbides, thereby affecting the grindability of the high-vanadium steel. Erasteel GV3 steel controls the nitrogen content below 70 ppm, while P30 steel’s nitrogen content is as high as 200 ppm. Traditional cast high-vanadium steels often use multiple vacuum degassing processes to control nitrogen content in the molten steel, suggesting that there may still be room for improvement in P30 steel.

To obtain the full potential of P30 steel while not affecting the tapping performance, the times should be increased appropriately based on its specifications in the tap groove sequence, which would lead to low processing efficiency.

Table 4: Cutting Life of M8 Uncoated Taps (2.5P) in Processing 42CrMo Steel for P30 and 2030 Steels

| Grade | Serial No. | Reason for Stopping | Holes | Average Holes | Dispersion |

| P30 | 1 | Continuous noise, cutting cone, and calibration collar wear | 80 | 86.7 | 0.12 |

| 2 | Continuous noise, cutting cone wear, and large diameter scratching | 99 | |||

| 3 | Continuous noise, cutting cone wear, calibration collar deformation | 81 | |||

| HOP2030 | 1 | Continuous noise, cutting cone wear, calibration collar, multiple scratches | 90 | 94.7 | 0.15 |

| 2 | Cutting cone wear, calibration collar, multiple scratches | 111 | |||

| 3 | Cutting cone wear, calibration collar, multiple scratches | 93 | |||

| ASP2030 | 1 | Continuous noise, cutting cone edge collapse, wear, large diameter scratching | 84 | 87.7 | 0.06 |

| 2 | Continuous noise, cutting cone, and calibration collar wear | 94 | |||

| 3 | Continuous noise, cutting cone edge collapse, and wear | 85 |

Test conditions:

Machine tool S500Z1, test blank 42CrMo,

Hardness 35.0- 38.0 HRC, effective tapping depth: 16mm, through hole, vegetable oil cooling.

Under higher speed (200 rpm):

Table 5: Cutting Life of M8 Uncoated Taps (2.5P) in Processing 42CrMo Steel for P30 and 2030 Steels

| Grade | Serial No. | Reason for Stopping | Holes | Average Holes | Dispersion |

| P30 | 1 | Chip sticking, cutting cone wear, large diameter scratching | 27 | 50 | 0.40 |

| 2 | Chip sticking, minor chipiing, cutting cone wear | 59 | |||

| 3 | Continuous noise, Chip sticking, cutting cone wear | 64 | |||

| HOP2030 | 1 | Chip sticking, continuous noise, cutting cone wear | 73 | 46.7 | 0.50 |

| 2 | Cutting cone wear, chip sticking | 28 | |||

| 3 | Chip sticking, cutting cone edge collapse, and wear | 39 | |||

| ASP2030 | 1 | Cutting cone wear | 99 | 73.7 | 0.52 |

| 2 | Minor chipping, chip sticking, cutting cone wear | 30 | |||

| 3 | Continuous noise, chip sticking, cutting cone wear | 92 |

Test conditions:

Machine tool S500Z1, test blank 42CrMo,

Hardness 35.0- 38.0HRC, effective tapping depth: 16mm, through hole, vegetable oil cooling.

Under higher speed (200 rpm):

The carbide morphology and size of HOP2030 powder high-speed steel is similar to that of ASP2030, and superior to that of P30 steel.

The hardness of HOP2030 steel after quenching and tempering under the same heat treatment conditions is almost the same as that of ASP2030 and 0.2 HRC higher than that of P30 steel.

P30 steels have relatively poor grindability compared with HOP2030 and ASP2030 steels.

At 110rpm, P30 steel taps the average tapping life is comparable to HOP2030 and AUD2030 steel taps.

At 200 rpm, the average tapping life of ASP2030 steel taps is 35% longer than domestic steel taps. P30 steel taps have a similar average life to HOP2030 steel taps, with comparable consistency.

The innovative processing technology of traditional casting high-vanadium and high-cobalt high-speed steel process has certain development potential, as suggested by this experiment.

And although far from exhaustive, the experiment did provide several data points comparing the performance of the two domestic high-speed steels to Erasteel ASP2030 steel in “tapping” applications. Controlling and processing the nitrogen content in P30 steel can improve its tapping performance.