Japan SUS440C dia20mm 100times

carbide size:32μm

carbide distribution:1.5 일본

A good knife is a must-have tool for outdoor exploration, survival training, camping, or wilderness cooking in outdoor activities.

ZEICIN specializes in the research and production of high-performance martensitic stainless steel materials, providing reliable and consistent steel solutions for high-end outdoor knife manufacturers worldwide.

We offer internationally acknowledged grade steel such as SUS440C, VG10, and 9Cr18MoV, which is equal to or even overperforms the Japanese-imported ones. These steels are very popular in knives for tactical knives, survival knives, fishing knives, camping knives, and many more.

| International Grade | China Grade | C Carbon | Cr Chromium | Mn Manganese | Si Silicon | Mo Molybdenum | V Vanadium | Co Cobalt | S Sulphur | P Phosphorus | Ni Nickel | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SUS420J2 | 3Cr13 | 0.26~0.35 | 12.00~14.00 | ≤1.00 | ≤1.00 | ≤0.03 | ≤0.035 | |||||

| 1.4116 | JXS05-15MoV | 0.45-0.55 | 14.00-15.00 | ≦1.00 | ≦1.00 | 0.50-0.80 | 0.10-0.20 | ≦0.030 | ≦0.035 | |||

| 6Cr14 | JXS06-14 | 0.65-0.70 | 13.00-14.00 | ≦1.00 | ≦1.00 | ≦0.030 | ≦0.035 | |||||

| AUS6 | JXS06-14MoV | 0.58-0.65 | 13.00-14.00 | ≦1.00 | ≦1.00 | 0.10-0.30 | 0.10-0.20 | ≦0.030 | ≦0.035 | |||

| AUS10 | JXS10 | 0.95-1.1 | 13.00-14.00 | ≦1.00 | ≦1.00 | 0.10-0.30 | 0.10-0.20 | ≦0.030 | ≦0.035 | |||

| AUS10Co | JXS10Co | 0.95-1.1 | 13.00-14.00 | ≦1.00 | ≦1.00 | 0.20-0.25 | 0.10-0.20 | 0.15-0.25 | ≦0.030 | ≦0.035 | 0.05-0.12 | |

| 9Cr13MoVCo | JXS09-13Co | 0.88-0.95 | 13.00-14.00 | ≦0.80 | ≦0.80 | 0.10-0.30 | 0.10-0.20 | 0.15-0.25 | ≦0.030 | ≦0.035 | ||

| SUS440A | 7Cr17MoV | 0.65~0.70 | 16.40~17.10 | 0.40~0.80 | ≤1.00 | 0.50~0.60 | 0.10~0.30 | ≤0.01 | ≤0.02 | ≤0.40 | ||

| SUS440B | 8Cr14MoV | 0.75~0.80 | 13.50~14.50 | 0.20~0.80 | ≤0.80 | 0.40~0.50 | 0.10~0.30 | ≤0.04 | ≤0.03 | ≤0.60 | ||

| 9Cr14MoV | 0.88~0.92 | 13.50~14.50 | 0.20~0.80 | ≤0.80 | 0.40~0.50 | 0.10~0.30 | ≤0.04 | ≤0.03 | ≤0.60 | |||

| 9Cr14MoV+Co | 0.88~0.92 | 13.50~14.50 | 0.20~0.80 | ≤0.80 | 0.40~0.50 | 0.10~0.30 | 0.20~0.30 | ≤0.04 | ≤0.03 | ≤0.60 | ||

| SUS440C | 9Cr18MoV (SUS440C) Kitchen knife | 0.85~0.95 | 17.00~19.00 | 0.20~0.80 | ≤0.80 | 1.00~1.30 | 0.07~0.12 | ≤0.04 | ≤0.03 | <0.40 | ||

| SUS440C | 9Cr18Mo (SUS440C) Hair scissor | 0.95~1.10 | 16.00~18.00 | 0.30~0.70 | ≤0.80 | 0.40~0.70 | ≤0.03 | ≤0.04 | <0.40 | |||

| SUS440C | 11Cr17 (linear guideway) | 0.95~1.2 | 16.00~18.00 | <1.00 | ≤1.00 | <0.75 | ≤0.03 | ≤0.025 | <0.60 | |||

| 440F | 0.95~1.2 | 16.00~18.00 | ≤1.25 | ≤1.00 | <0.75 | ≤0.15 | ≤0.060 | ≤0.60 | ||||

| 85Cr18Mo2V | 0.80~0.90 | 16.50~18.50 | 0.90~1.40 | ≤0.80 | 2.00~2.50 | 0.30~0.60 | ≤0.03 | ≤0.04 | <0.40 | |||

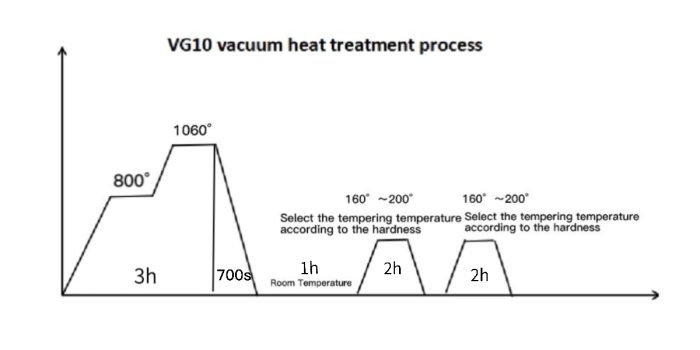

| VG10 | VG10 | 0.95~1.05 | 14.50~15.5 | 0.30~0.50 | ≤0.80 | 0.80~1.20 | 0.25~0.35 | 1.30~1.80 | ≤0.025 | ≤0.025 | <0.50 | |

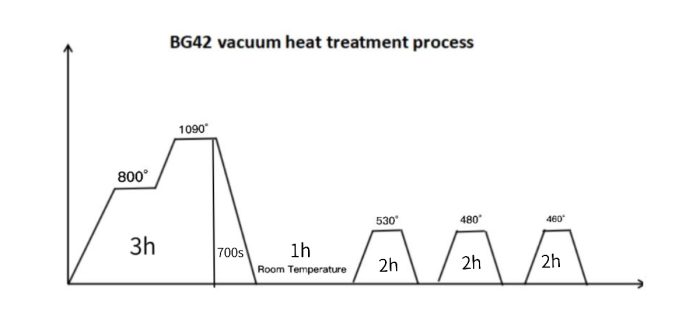

| BG-42 | BG-42 | 1.10~1.20 | 14.0~15.0 | 0.30~0.60 | 0.20~0.40 | 3.75~4.25 | 1.10~1.30 | ≤0.010 | ||||

| S35VN | S35VN | 1.32~1.42 | 13.70~14.30 | 0.40~0.60 | 0.40~0.60 | 1.95~2.05 | 2.90~3.10 | ≤0.025 | ≤0.025 | ≤0.25 |

When it comes to outdoor adventure, survival, and camping, a dependable knife to cut through a variety of tasks is a must-have. Zeicin is good at high-performance martensitic stainless steel like SUS440C, VG10, and 9Cr18MoV, are now very popular in advanced outdoor knives, high-end knives. and has the following advantages:

Premium quality material high in chromium for great resistance against moisture, rain, and chemicals to keep the knife sharp and free from rust.

The high hardness of the knives makes them feel super sharp and durable in rugged conditions with heavy force.

With a smooth, stainless surface, the steel resists dirt and rust, making outdoor maintenance simple and efficient.

Tolerance to twisting, bending, and shattering that far exceeds that of both thermoplastic and thermoset products means maximum performance in outdoor applications.

Advanced Smelting Technology: Our steel is refined through a three-stage process (EAF + LF + VD), followed by Zeicin’s proprietary RS-ESR method, resulting in purity levels far beyond industry standards.

Innovative Forging Process: Unlike conventional rolling, we apply deformation forging to refine carbide distribution, greatly enhancing strength and impact resistance.

Exceptional Cost-Performance Ratio: Our steels match or exceed the performance of Japanese brands like VG10 and 440C, while offering more competitive pricing and faster delivery.

Knives are useful tools in wild survival. They can be used to construct temporary shelters, fashion tools and weapons, prepare foo,d and more. A good, strong, versatile survival knife is essential for dealing with the unexpected in the wild.

Knives are indispensable utensils for outdoor cooking, used for slicing, chopping, and preparing ingredients, enhancing the joy of outdoor dining. A lightweight, portable outdoor cooking knife facilitates chefs in handling ingredients with ease, allowing them to enjoy delicious outdoor meals.

Knives can be used in emergencies for self-rescue or to assist others. For example, they can be utilized to slash ropes, snip bandages, scrub wounds, and more. When it comes to outdoor adventures, the last thing you need is a sudden equipment fail, making a durable knife become the knife of last resort.

Field knives are a relic of the past that actually offer a lot of versatility as more than just a cutting solution. From making sharp sticks and scraping stumps to fixing broken gear and sharpening other tools, a durable all-purpose knife makes work more manageable when untamed wilderness puts a rope in your hand.

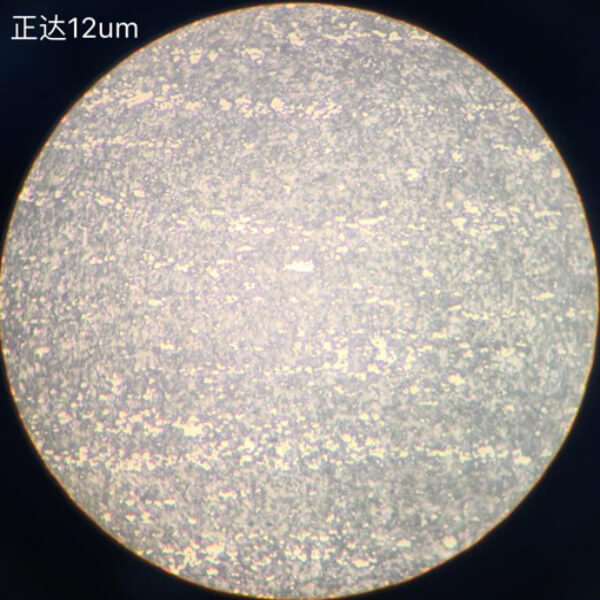

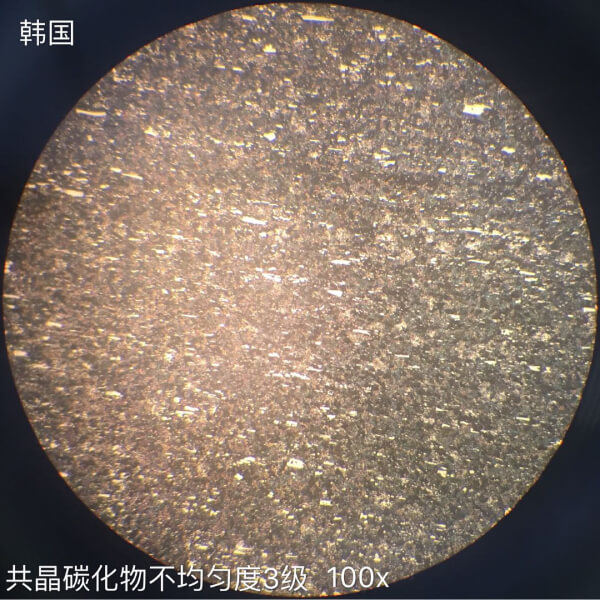

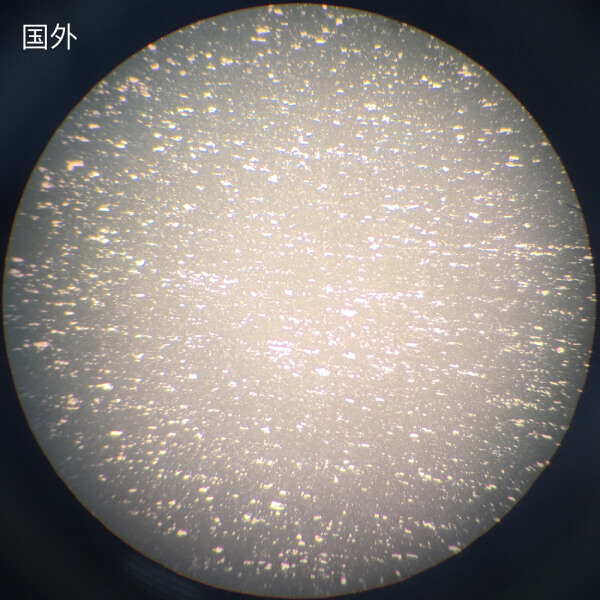

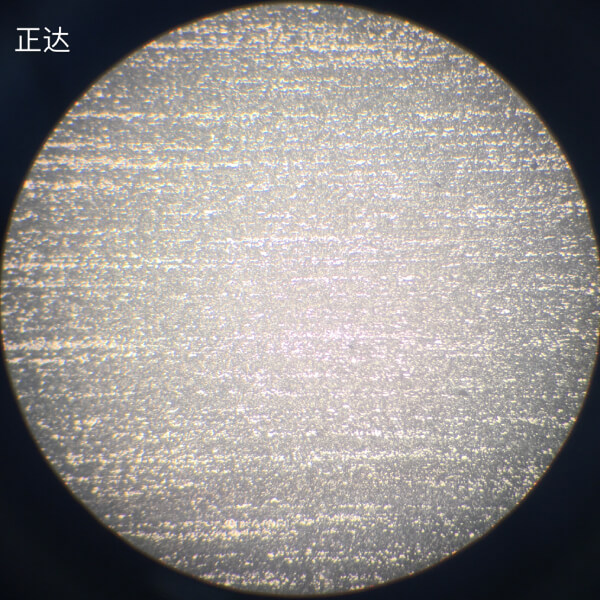

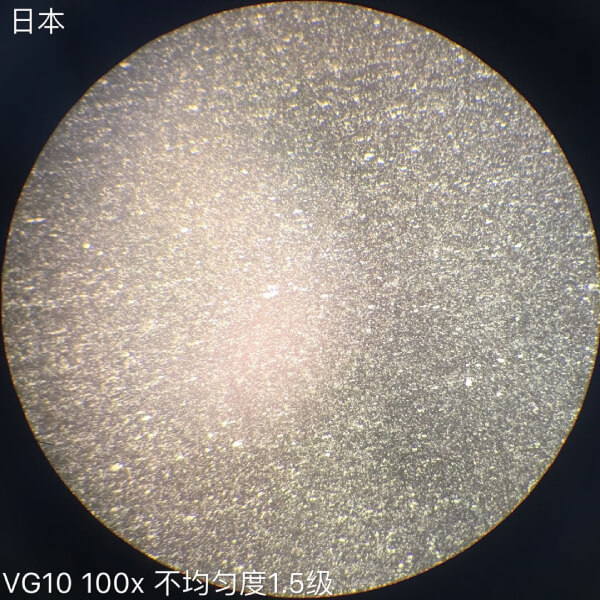

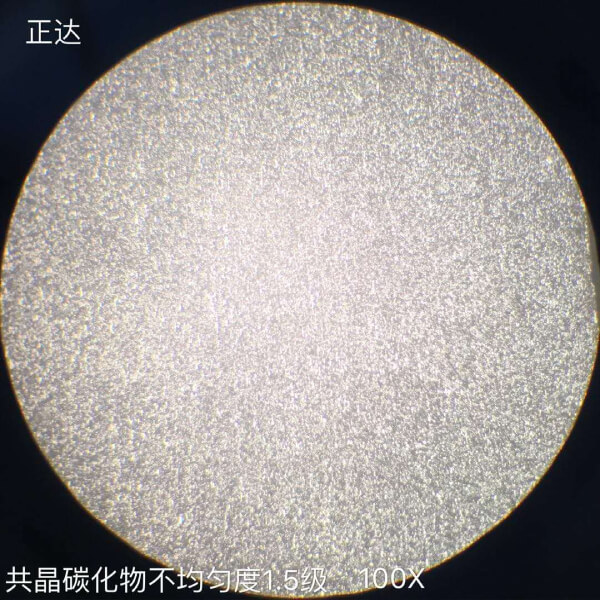

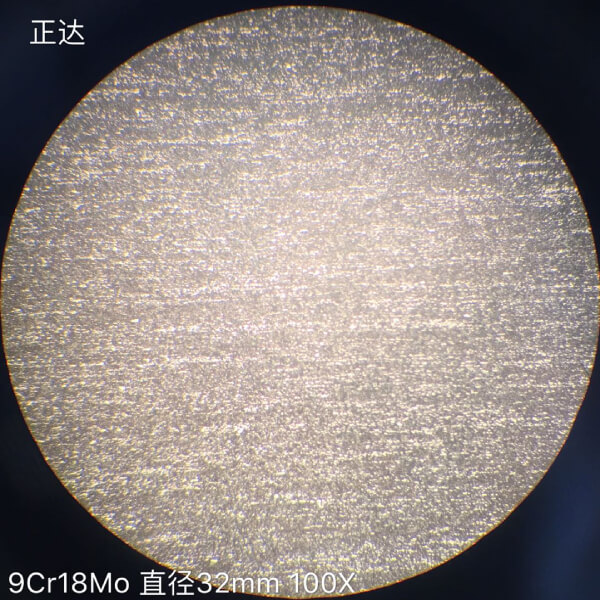

Image description: 9Cr18Mo X100 times carbide analysis.

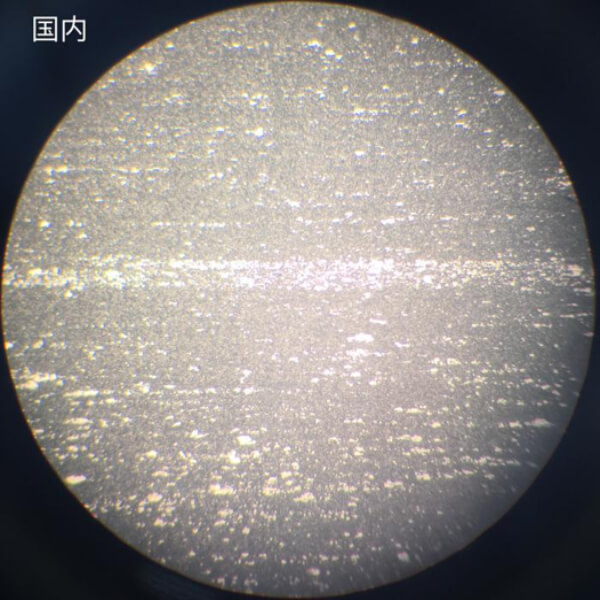

Photo1(Domestic). Carbon carbide size obviously appears big size.

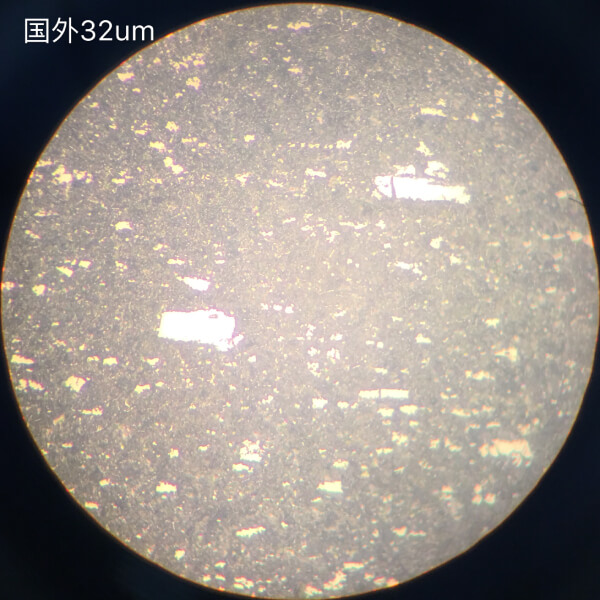

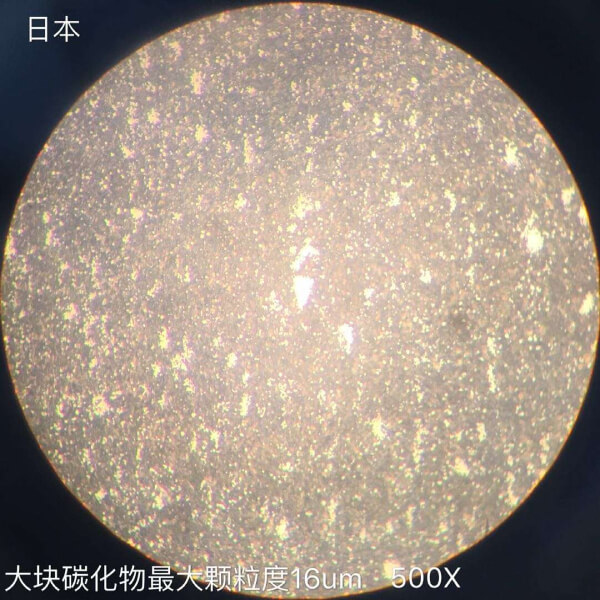

Photo 2 (abroad), the carbide distribution is uneven, and the individual is large. Reason analysis: During the smelting process, the carbide can not be controlled well. In the late forging, although the forging ratio increases, it fails to make up for the defects of the smelting.

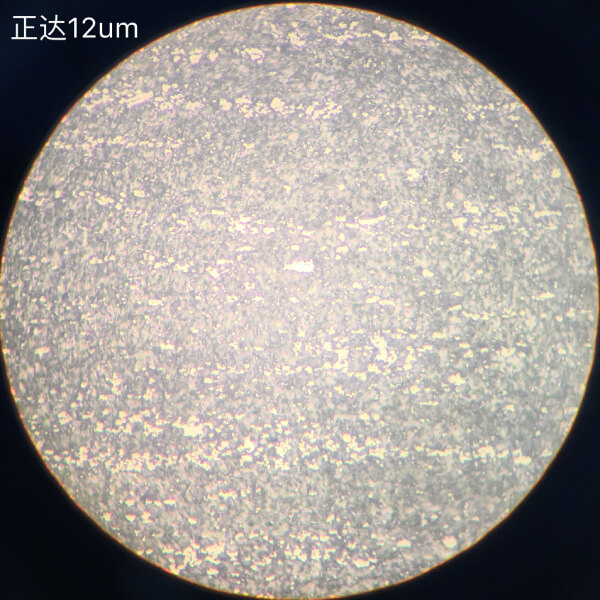

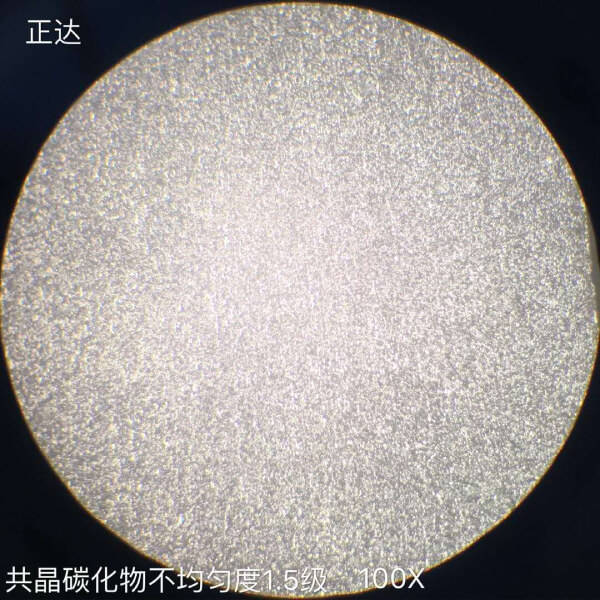

Photo3(ZhengDa=Zeicin), the modification of the three technological processes of

1)EAF+LF+VD

2) Special innovation smelting process of RS ESR,

3) Transformation forging of the 9Cr18Mo, which is obviously better than the imported ones. The carbide is small and uniform.

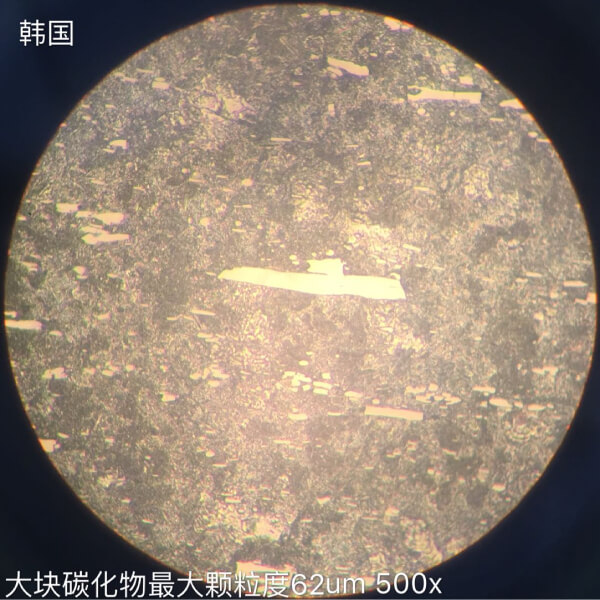

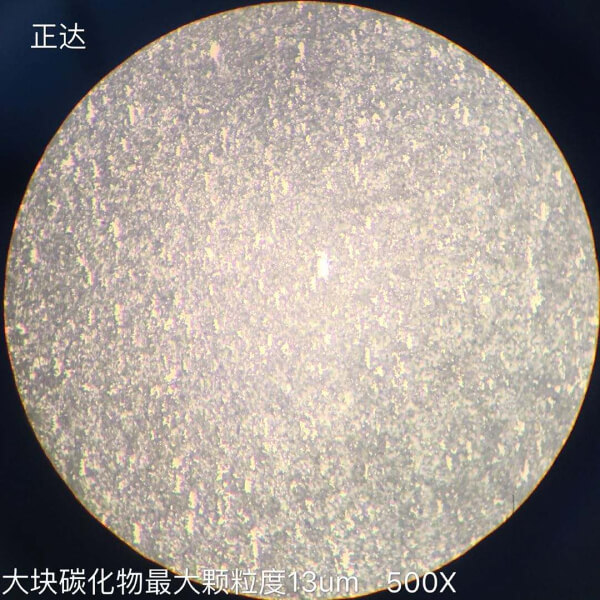

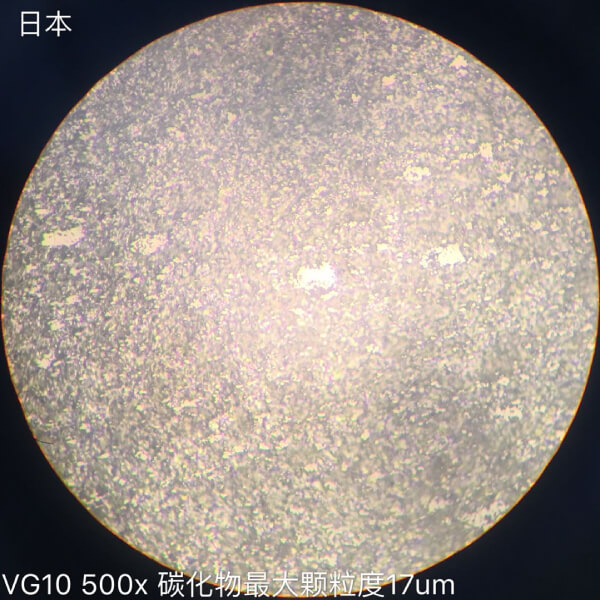

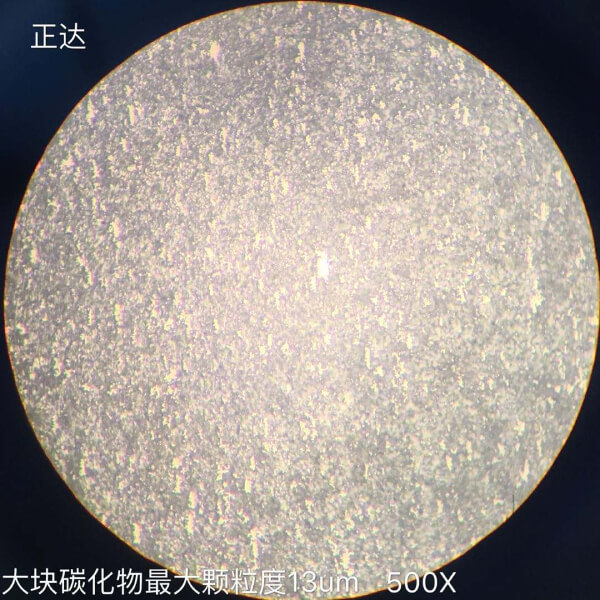

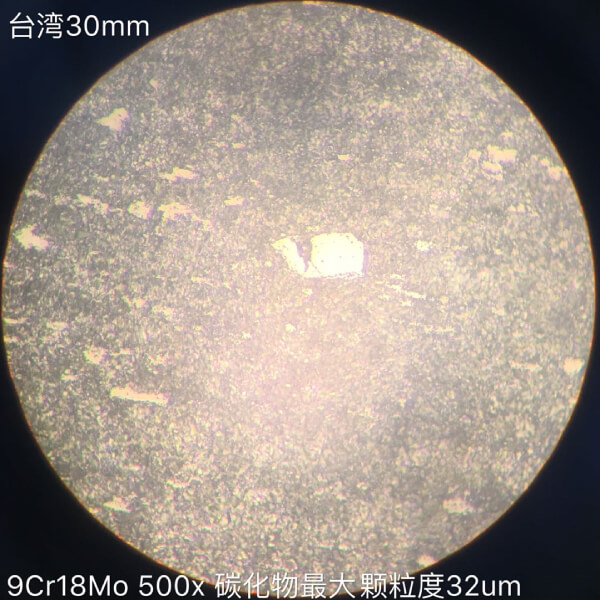

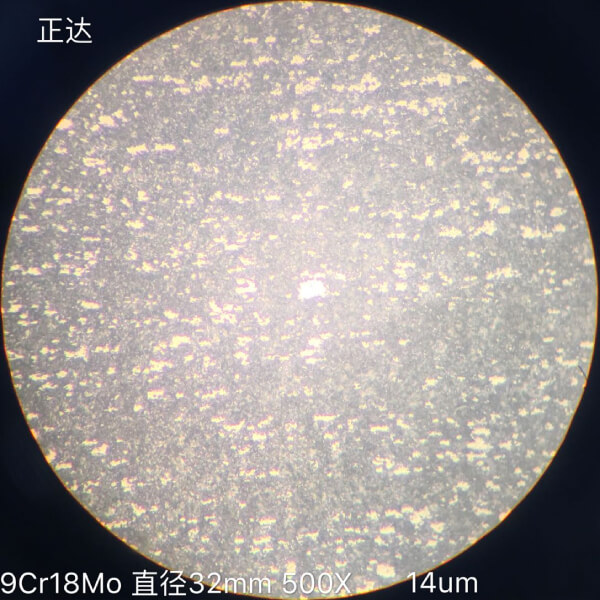

Image description: 9Cr18Mo X500 times carbide analysis

Photo 1 (domestic), the carbide individual is obviously large, and the processing will result in the phenomenon of detachment.

Photo 2 (abroad), The carbides are superior to domestic ones, but there are more angular carbides, and cracks and stress concentrations are easy to occur in use, leading to early failure.

Photo3(ZhengDa=Zeicin), the modification of 9Cr18Mo in the process of smelting and forging, the level of carbide is obviously superior to the imports.

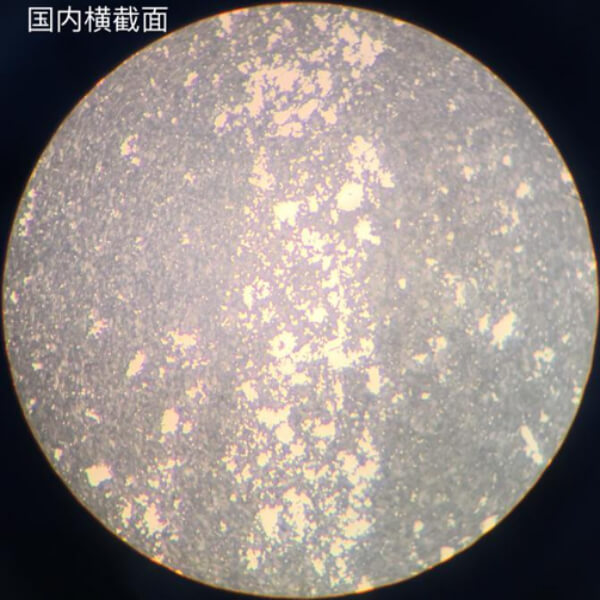

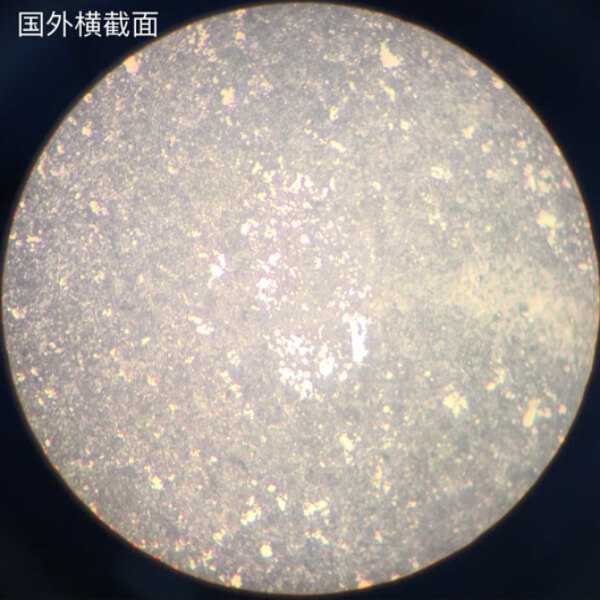

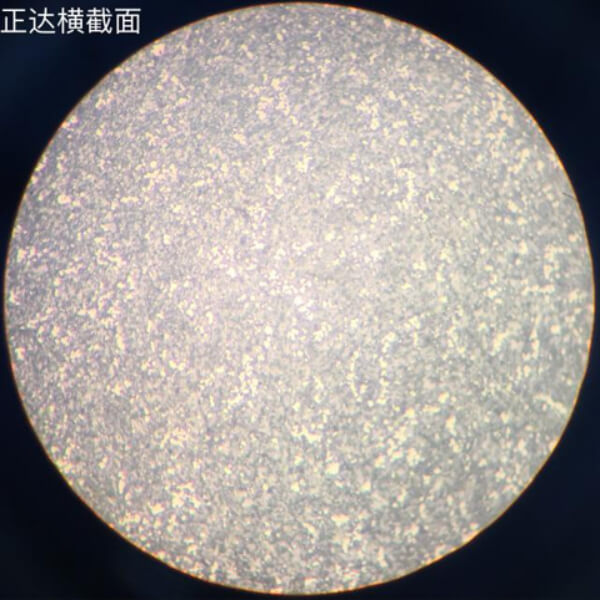

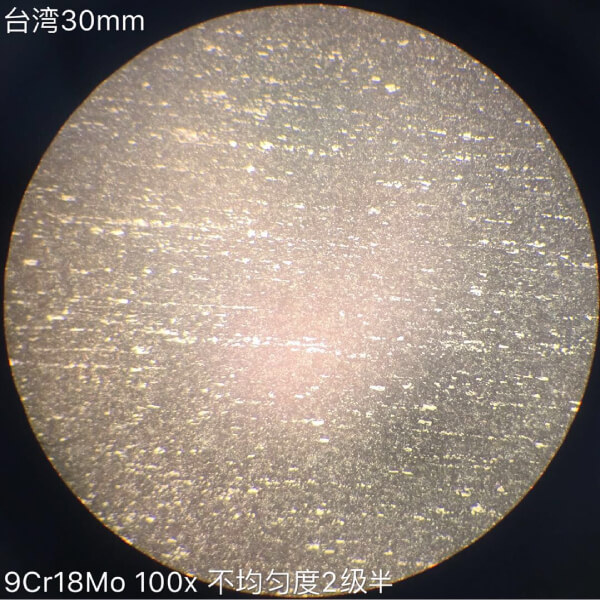

Image description: 9Cr18Mo X100 times cross-section carbide analysis.

Photo 1 (domestic), Zonal carbides are obvious, the carbide particles are obviously larger than the longitudinal ones, cause analysis: no modification of forging, just rolling directly.

Photo 2 (abroad), the distribution of carbides is not uniform, and the individual is large. Reason analysis: During the smelting process, the carbide can not be controlled well. In the late forging, although the forging ratio increases, it fails to make up for the defects of the smelting.

Photo3(ZhengDa=Zeicin), the modification of the three technological processes of

1) EAF +LF+VD

2) Special innovation smelting process of RS ESR

3) Transformation forging of the 9Cr18Mo, which is obviously better than the imported ones. The carbide is small and uniform.

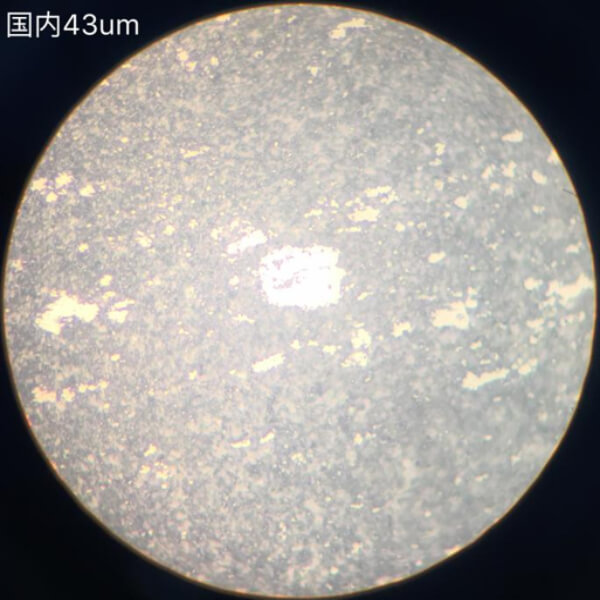

Korea SUS440C dia20mm 100times

carbide size:62μm

carbide distribution:3 한국

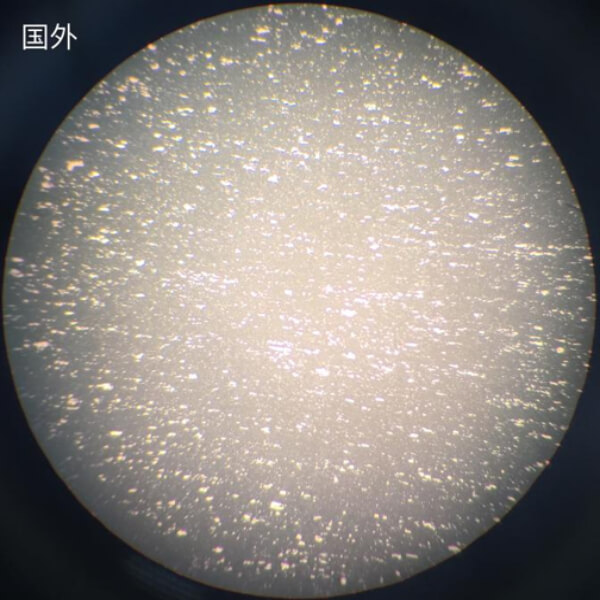

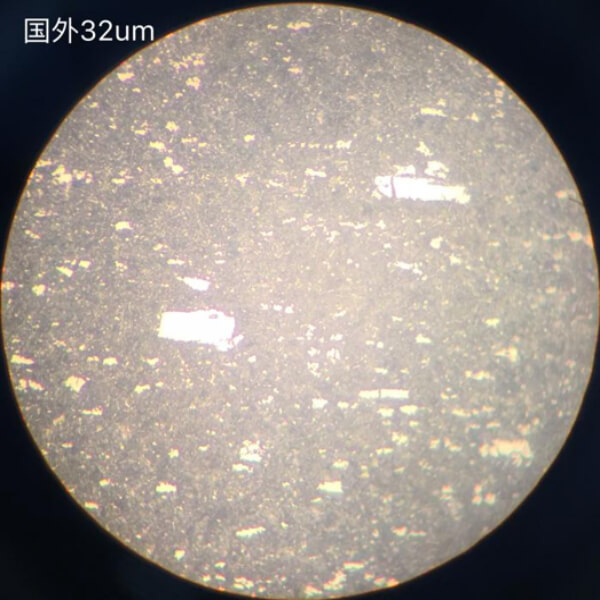

Japan SUS440C dia20mm 100times

carbide size:32μm

carbide distribution:1.5 일본

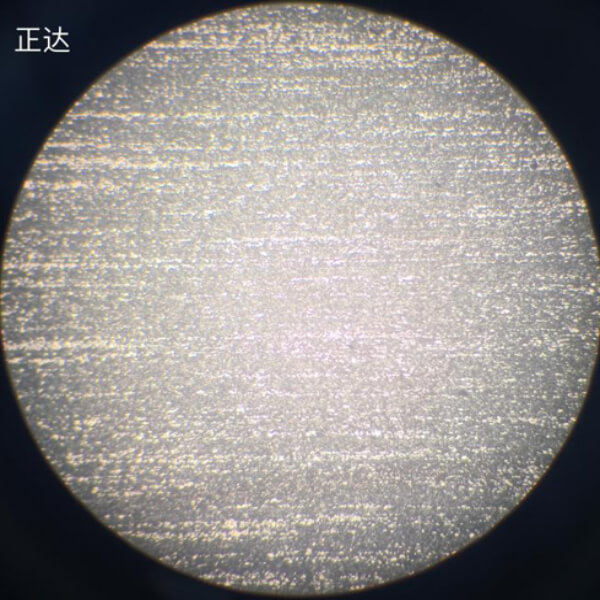

Zeicin SUS440C dia20mm 100times

carbide size:12μm

carbide distribution:2 정다몰드

Korea SUS440C dia20mm 500times

carbide size:62μm

carbide distribution:3 한국

Japan SUS440C dia20mm 500times

carbide size:32μm

carbide distribution:1.5 일본

Zeicin SUS440C dia20mm 500times

carbide size:12μm

carbide distribution:2 정다몰드

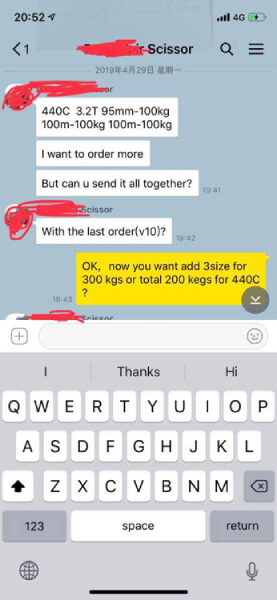

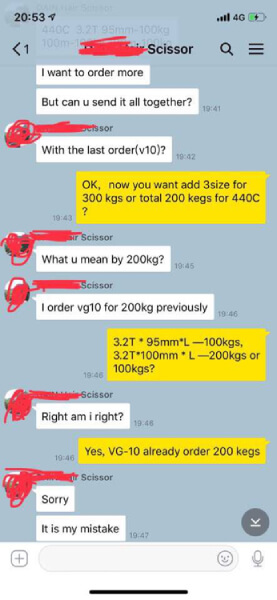

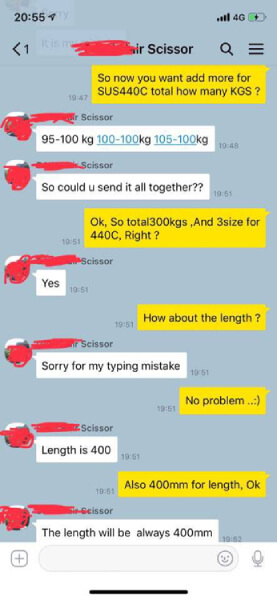

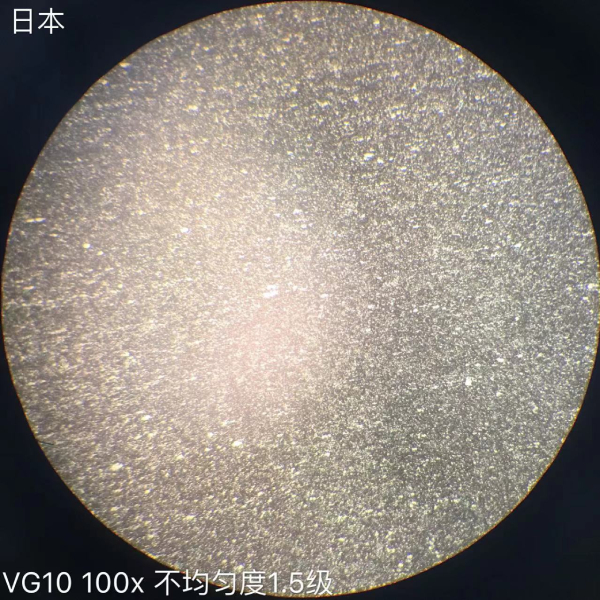

Japan VG-10 dia22mm 100times

carbide size:16μm

carbide distribution:1 일본

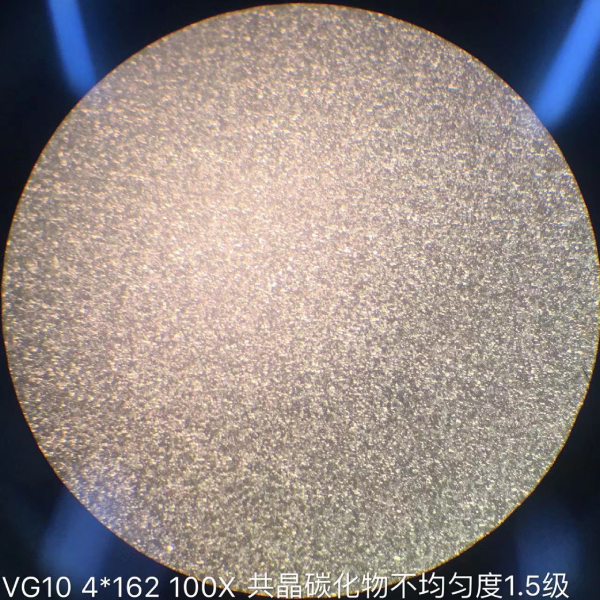

Zeicin VG-10 dia22mm 100times

carbide size:13μm

carbide distribution:1.5 정다몰드

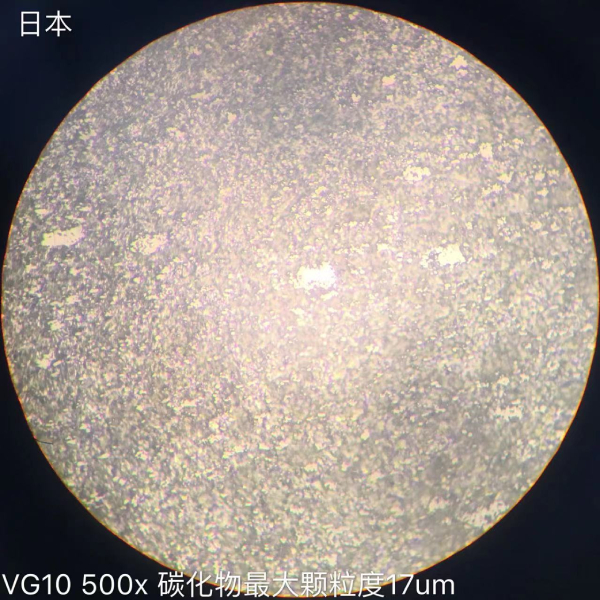

Japan VG-10 dia22mm 500times

carbide size:16μm

carbide distribution:1 일본

Zeicin VG-10 dia22mm 500times

carbide size:13μm

carbide distribution:1.5 정다몰드

Takefu 440C

dia3.3X105XLmm 100times

carbide size:17μm

carbide distribution:1.5

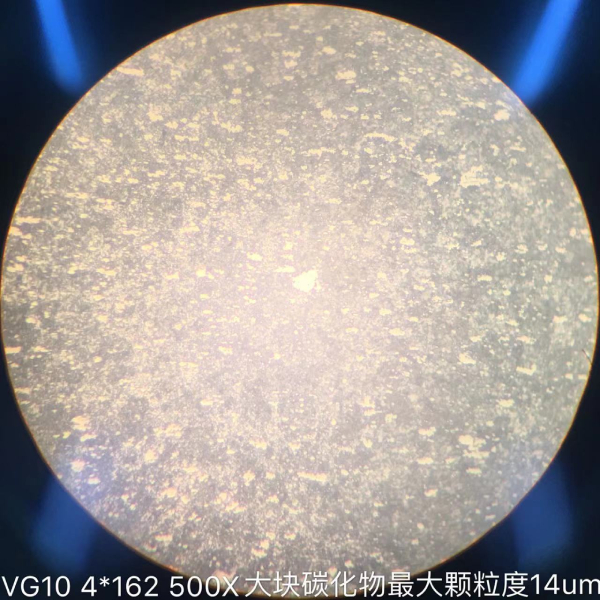

Zhengda=Zeicin VG-10

dia3.3X160XLmm 100times

arbide size:13μm

carbide distribution:1.5

Gloria 440C

dia30mm 100times

carbide size:32μm

carbide distribution:2 .5

Zhengda=Zeicin 440C

dia32mm 100times

carbide size:14μm

carbide distribution:2

Takefu 440C

dia3.3X105XLmm 500times

carbide size:17μm

carbide distribution:1.5

Zhengda=Zeicin VG-10

dia3.3X105XLmm 500times

carbide size:13μm

carbide distribution:1.5

Gloria 440C

dia30mm 500times

carbide size:32μm

carbide distribution:2 .5

Zhengda=Zeicin 440C

dia32mm 500times

carbide size:14μm

carbide distribution:2

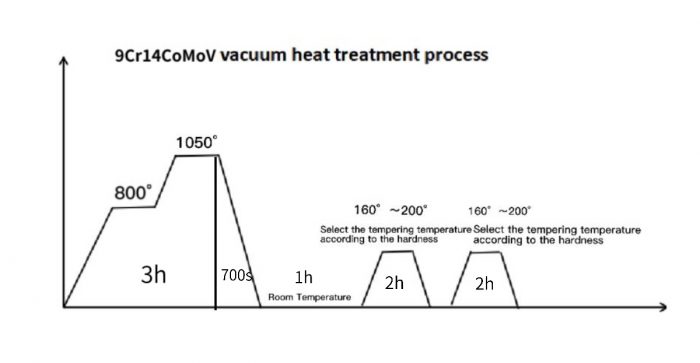

The advantages of choosing 9Cr14MoV+Co:

1) It is not easy to break when it is used for warping bending shear;

2) The matrix strength is higher;

3) The toughness is better