When working in the cutting field, having a sharp and efficient blade is the most important aspect.

ZEICIN High Carbon Steel Tool blades are not inferior to top international brands in quality, and have a great price advantage.

Our blades are crafted using unique technological processes and stringent quality control to ensure durability and sharpness in every cut.

We start from the source of steel smelting, it is because of the performance of raw steel control, so the supporting brother factory with better quality and a special grinding process, makes our blades different.

As a source factory, this product, from steel smelting to the final factory rotary cutting blade production, will make the blade in the production of the raw materials, the heat treatment process and the necessary grinding function, hardness, wear faster and so on, so as to ensure the quality and grinding speed and lifetime of the cutting blade production processes, as these processes can ultimately impact the cutting blades of the late finished products.

In terms of raw materials, we use imported high-quality steel as raw material, use high-speed steel, hard alloy steel, and other materials as raw materials, which use their high hardness, wear resistance.

Our exclusive grinding process significantly extends the life of our blades during blade production. Use the same price to buy a longer-lasting, more durable, and more cost-effective quality knife.

ZEICIN High Carbon Tool Steel blades are made from premium high-speed steel and hard alloy steel, which provide unparalleled cutting performance due to their exceptional hardness and wear resistance. We employ advanced technologies in steel smelting and processing to ensure each blade meets rigorous quality standards.

ZEICIN rotary blades are designed to provide a smooth and effortless cutting process. The precision-engineered blade reduces wear and dulling, ensuring long-lasting sharpness and efficiency in every cut.

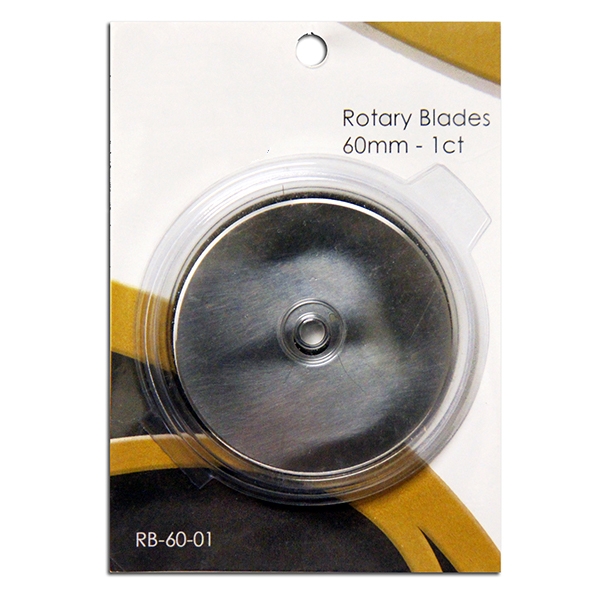

There are 3 sizes of ZEICIN blades (28mm,45mm and 60mm) to choose, so you can achieve different cutting needs according to your own preference in different scenes.

ZEICIN used stringent quality control standards, regulated with a quality management system in every process, from smelting steel to blade production, ensuring that each blade delivers stable, sharp, and long-lasting cutting performance.

ZEICIN blades are equipped with safety covers or adjustable guards to minimize the risk during use, ensuring user safety and confidence.

In blade manufacturing, the choice of steel determines the performance of the blade. ZEICIN’s choice of SKS-7 high-carbon tool steel ensures that our blades are industry-leading in terms of hardness, wear resistance, and cutting accuracy.

The blade is made of high-quality SKS-7 steel, it’s durable and has a long-lasting edge and cuts effectively even when subjected to high-stress loads. It’s also got great wear resistance, which will increase the life of the blade.

Material: SKS-7 Steel Our blades are made of extremely hard SKS-7 Steel, which ensures a precise cut with the maximum stability and security of the resulting cutting process.

The SKS-7 steel is treated to a high level of quality, which promotes edge retention in use and gives high durability in applications.

By choosing SKS-7 high carbon tool steel, our blades not only exceed conventional blades in terms of hardness and wear resistance, but also provide superior cutting results in a variety of application scenarios. Whether it’s for sewing, craft making, home and office use, or handling hard materials, SKS-7 excels.

ZEICIN High Carbon Tool Steel blades are top in the cutting and sewing world.

Rotary Cutter Blades are preferred tools for both professionals and home sewing enthusiasts due to their efficiency and precision.

Our blades effortlessly cut through multiple layers of fabric, avoiding uneven cuts and fraying edges often associated with traditional scissors.

For instance, our fabric cutter and fabric cutters are perfect for cutting through a variety of fabrics, ranging from delicate silk to tough cotton.

Suitable Fabrics: Cotton, linen, silk, wool, etc.

Common Uses : Cutting garment patterns, quilting, fabric craft projects

In artisan production and creative work, ZEICIN High Carbon Tool Steel blades also excel. Our cutters’ blades are designed to cut perfectly paper, cardstock, stickers, decals, and other craft materials.

The dependable cutting action delivers accurate cuts for professional-quality designs and patterns, every time, helping artists and crafters fulfill their creative dreams.

Whether using a Roller knife or an art knife, we ensure precise and efficient cutting results.

Whether using a Roller knife or an art knife, we ensure precise and efficient cutting results.

Suitable Materials: Colored paper, cardstock, foam board, stickers, etc.

Common Uses: Making handmade cards, scrapbook layouts, and paper art decorations.

Have cutting performance for Tough materials such as leather or cutting performance with these ZEICIN High Carbon Tool Steel rotary cutter Blades.

Ideal for leather work or for cutting thick cardboard and ply, our blades will leave you with the perfect cut every time.

Our products have proven their excellent durability and cutting precision in actual use.

For different materials, our material rotary cutter and cutter for fabric handle various cutting needs effectively.

Suitable Materials: Leather, thick cardboard, plywood, etc.

Common Uses: Crafting leather accessories, creating decorations, and cutting thick cardboard.

Our special grinding method maintains the sharpness and durability of our knives.

Compared with traditional knives, our vertical and surface grinding can help reduce the cutting and increase the service life of knives.

These are the technological advantages that make our blades comparable and superior to the high-level blades from Japan and Europe; at the same time, the better cost-effectiveness makes us your better choice.

Vertical Grinding Process

Surface Grinding Process

Features: The use of a surface grinding machine, through the horizontal grinding wheel to grind the blade, is suitable for the application of the blade surface flatness requirements.

Q1: How to install the Rotary Cutter Blade?

A1: As long as the mechanism is not damaged or is of good quality, you should only have to press the release button on the tool or spin the holder to remove the old blade and attach a new one. Select a bit, ensure the bit is level and anchored before use.

Q2: What should I do when the blade gets dull while cutting?

A2: Blade dulling is normal. You can sharpen the blade with a sharpening tool or change the blade to a new one.

A3: Will different materials need different blades?

A3: Yes, different materials do have different blade needs. For instance, tougher stuff (like leather) calls for more durable blades, while so-called softer stuff (like fabric) needs sharper blades.

ZELCIN High Carbon Tool Steel blades have been widely acclaimed by domestic and foreign customers.

They were able to tell us that our blades have brought a new efficiency to production, and cut the cost as well!

And here are a selection of customer reviews:

“ I am blown away by the cutting capabilities of ZEICIN High Carbon Tool Steelblades, particularly with multiple layers of fabric. It performs very stably.”

“We employed these knives for artistry and were very pleased with the performance. Placing our materials with the cut-by-cut precision that you wouldn’t know could be so satisfying we could reach a new level of craftsmanship.”