Our Projects

The raw material innovation technology of our company is unique and professional, ranging from the R&D and production of raw materials to the production of finished products can achieve an integrated production line. We provide high cost-performance, high-performance and high-quality service that can replace products made in Japan and Western nations.

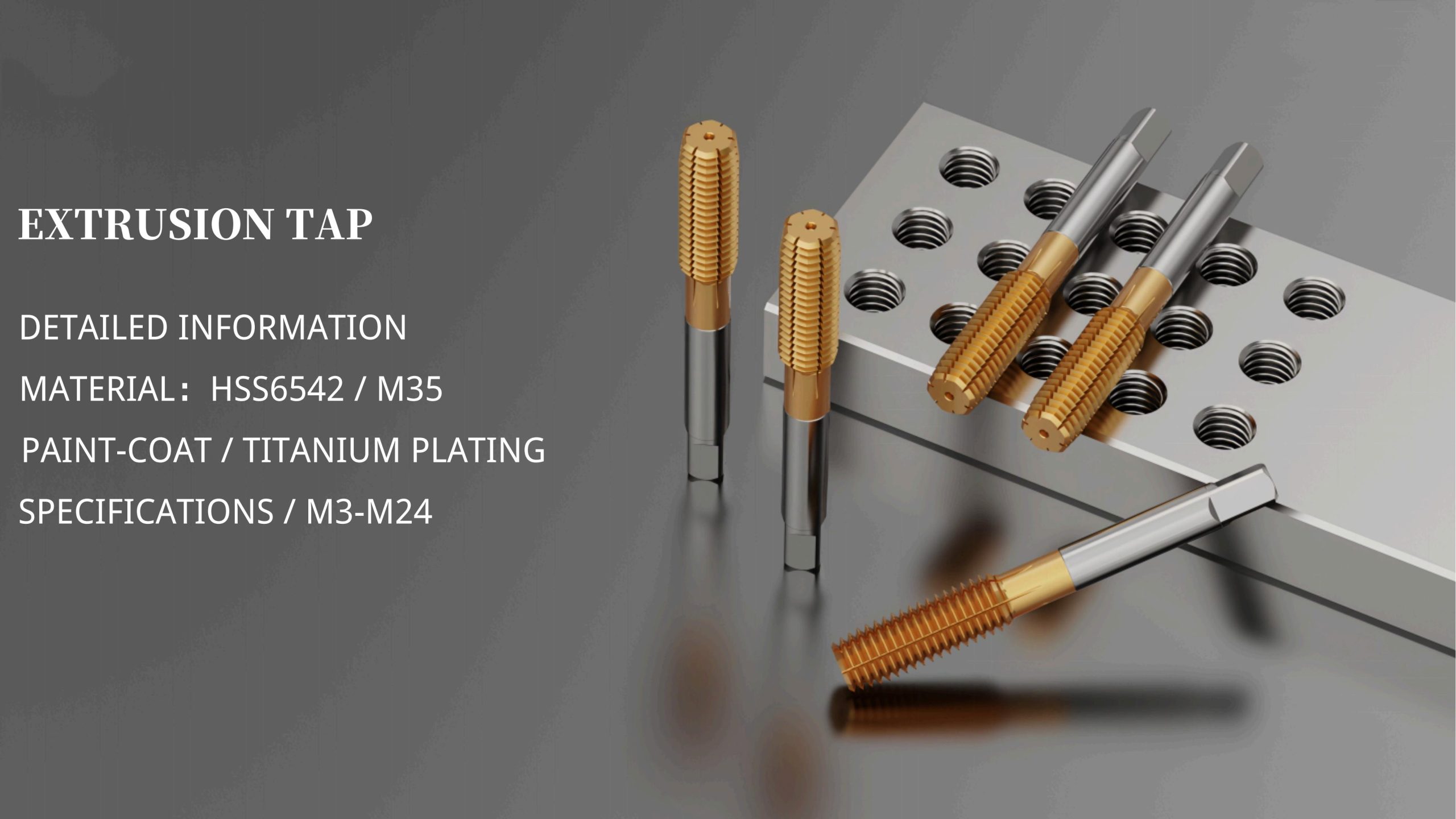

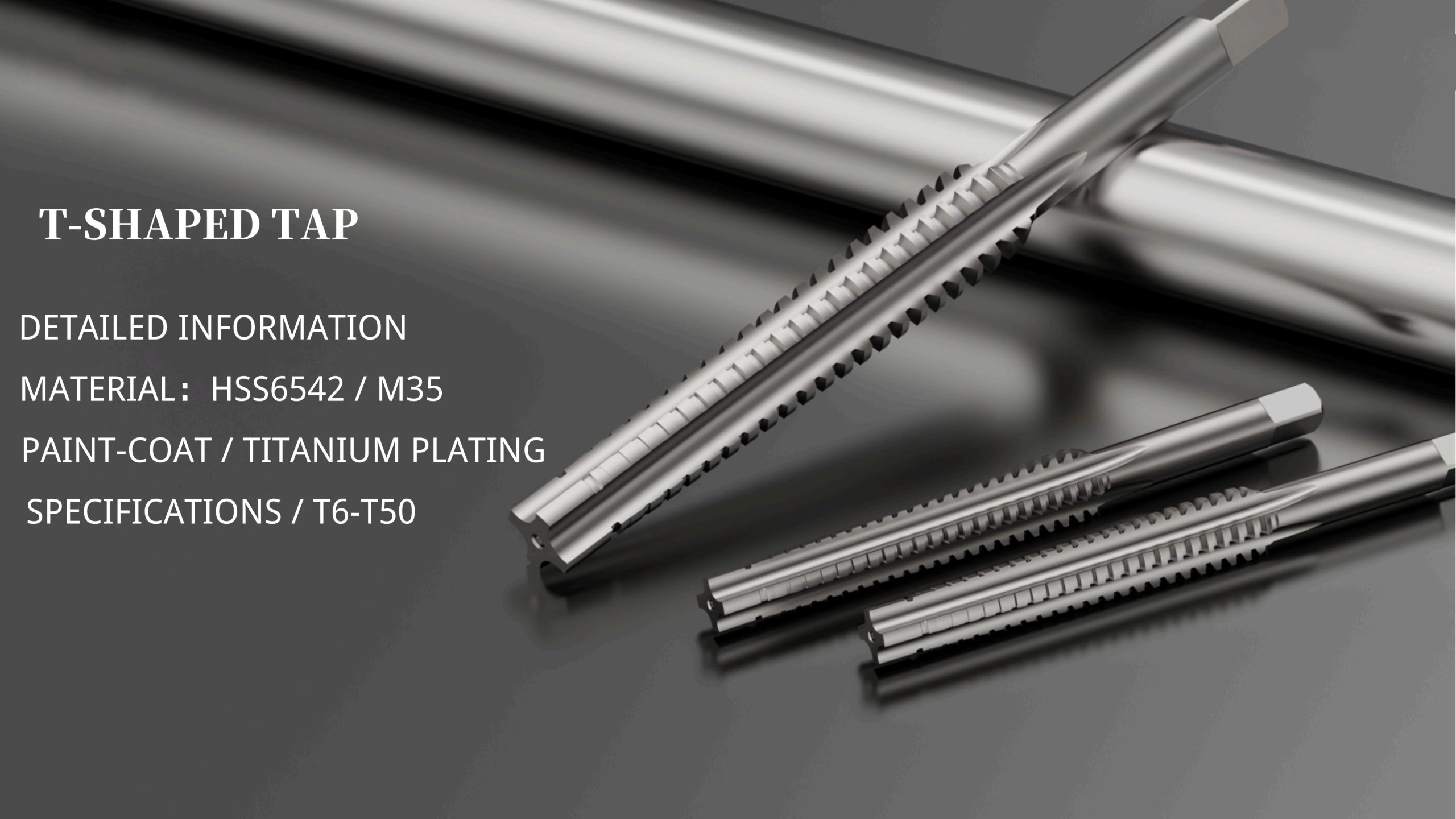

Therefore, we invest in the production of high-speed steel punching rod workshop, and jointly produce high-speed steel tap, high-speed steel drill and other cutting tool products with brother factories.

Maximum service life of high-speed steel tap, two or three times than the peer high-speed steel tap, let your production line is more stable, reduce production costs, improve production efficiency and win the market.

As the source manufacturer of high-speed steel materials, has the unique directional solidification electroslag remelting process, and accumulated 15 years of production experience, to ensure stable and reliable product quality, with domestic and foreign well-known customers praise and recognition. That's the right mix of tech and performance.

Our products can really replace similar products in Japan and Europe, with high quality, cost-effective, mature stability can help customers save costs and market competition advantage.

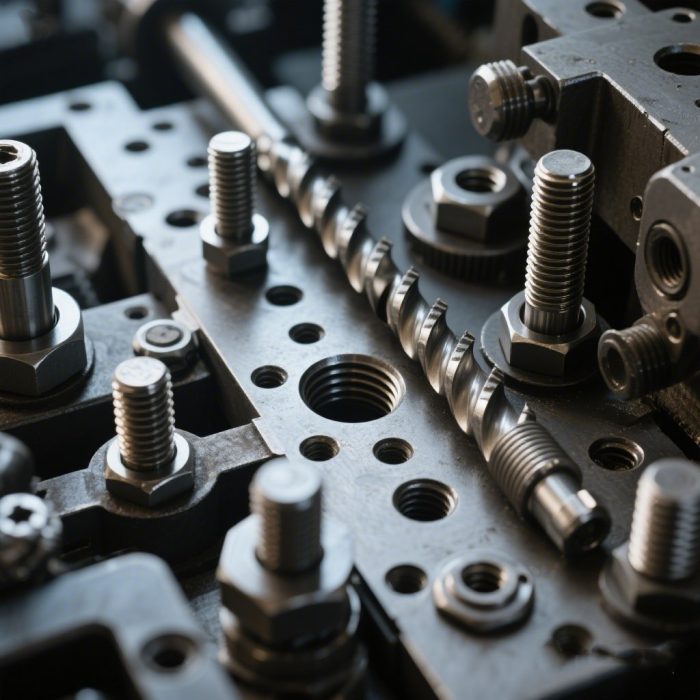

High-speed steel taps are mainly used in the industrial sector, including automotive wheel hubs, iron tower electric poles, water faucet fittings, bicycles, mechanical equipment fasteners, and other wide-ranging applications.

Automotive Hub Nut Tap:

It is used to machining the nut hole of the automobile wheel hub to ensure the firm connection between the wheel hub and the wheel nut, and to machining the thread to the engine cylinder block, transmission shell and other parts.

Iron Tower, Wire Pole Nut Tap:

In the construction of power tower, pole and other projects, used for processing nut holes to ensure the reliability and safety of power facilities.

Iron Tower, Wire Pole Nut Tap:

This is applied to process the nut holes in the faucet and its accessories to ensure that the faucet is tight, waterproof and prevent adverse water leakage.

The Nut Tap On The Bicycle:

This is used to process the nut holes on several parts of the bicycle — such as the nut used to lock the wheel hub, the nut used to lock the frame, etc., to ensure that the structure of the bicycle is stable. It facilitates manufacturing for an industry of bicycle making.

Mechanical Equipment Fastener Nut Tap:

For installation and maintenance of various mechanical equipment, processing fasteners (such as bolts engine since nuts) holes, in order to ensure the safety and stability of equipment operation.

Our high speed steel tap with advanced high-speed steel materials for cutting, cutting technology to ensure the cutting process to get efficient and accurate cutting effect, long life, greatly improving work efficiency.

High-speed tap is made of high-quality high-speed steel material, with high wear resistance and durability, good toughness and high precision, and high pass rate of taps. It can maintain sharp for a long time, minimize amendment and minimize use cost.

Our high-speed steel taps are precision machined and heat treated, with fully automatic CNC lathes to ensure smooth surfaces and precise dimensions, minimizing vibration and noise during cutting and improving machining quality.

High-speed steel tap, available specifications: different materials and processing requirements, can be customized according to customer requirements. We are committed to replacing raw materials such as HSS from a well-known French and Japanese brand with low cost and high quality.

This gives us a huge competitive edge in coatings. Thirdly, we bring advanced coating technology from Taiwan, which provides us strong technical support and quality assurance. Second, One-stop professional production and sales service. We are a raw material manufacturing, through production, product sales to after-sale service seamless connection to ensure product quality and delivery on time We have a team of experts with years of experience who are committed to offering personalized solutions and tailored services to our clients in order to ensure their satisfaction. Regardless what specific coating products customers need, we are able to fulfill them and serve them best quality service and support.