One of the commonly used tungsten high-speed steel is W18Cr4v, which is lactic steel, the longest used tungsten high-speed steels . They are sometimes known as “white steel”, “front steel”,”wind steel”(again an air-cooled hardened steel) like other high-speed steels.

W18Cr4V is an omni-directional steel that can be used for cutting when hot and hard requirements are less significant. W18Cr4V can also be used for cold service; Tool examples include punching, forming, stamping, etc.

| Execution Standard | ZEICIN Grade | GB | AISI | JIS | DIN |

|---|---|---|---|---|---|

| GB/T9943-2008 | T1 | W18Cr4V | T1 | SKH2 | 1.3355 |

| C | W | Mo | Cr | V | Co | Al | Mn | Si | S | P |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.73-0.83 | 17.20-18.70 | - | 3.80-4.50 | 1.00-1.20 | - | - | 0.10-0.40 | 0.20-0.40 | ≤0.03 | ≤0.03 |

| Type | Specification(mm) | Surface Condition |

|---|---|---|

| Cold-drawn Round Steel | φ2-10 | Black |

| Hot-rolled Round Steel | φ11-75 | Turned |

| Precision Forging Round Steel | φ80-120 | Turned |

| TW | 20 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|

| 3 | √ | √ | √ | √ | ||||||

| 4~5 | √ | √ | √ | √ | √ | √ | ||||

| 6~13 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 14 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 15~18 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 19 | √ | √ | √ | √ | √ | √ | √ | |||

| 20 | √ | √ | √ | √ | √ | √ | √ | √ |

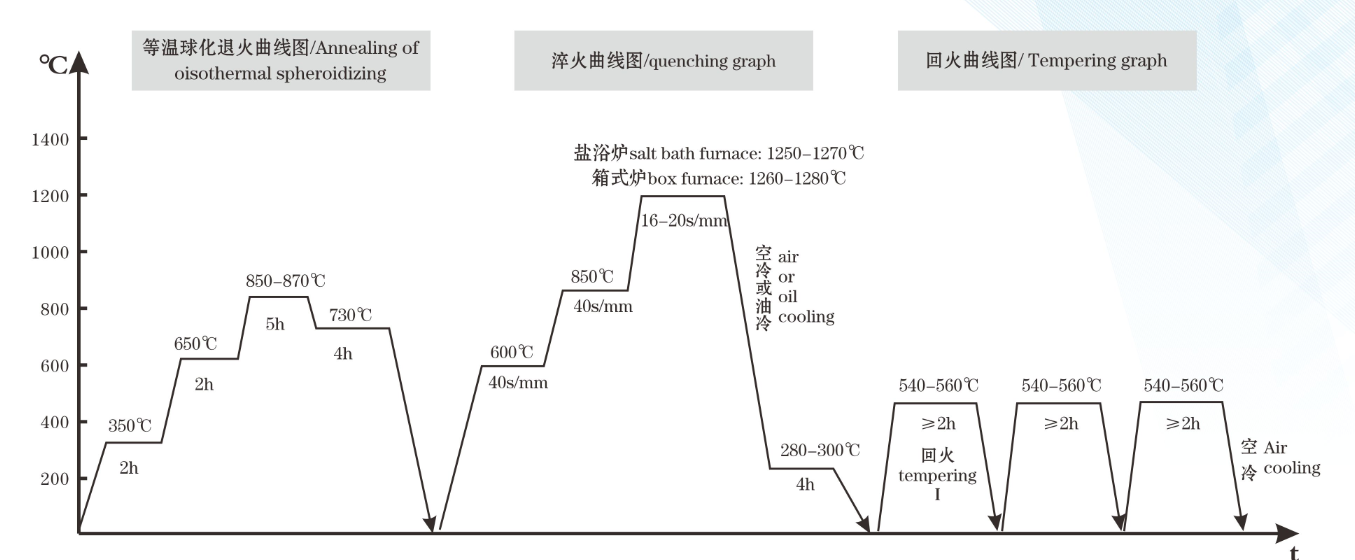

A highly-controlled heat treatment process allows T1 high-speed steel to reach the desired hardness, toughness, and wear resistance. This is done through several processes like Annealing, Quenching, Tempering etc, with each process requiring specific temperatures in order to produce a better quality end product.

Annealing:

Heat treatment of steelAustenite decompositionAustenite is held at 850-870°C for some hours and slowly cooled to 600°C to relieve internal stress and refine the carbide structure to improve machinability.

Quenching:

The steel is heated up to 850°C at first and then quickly raised up to either 1250–1270°C (salt bath furnace) or 1260–1280°C (box furnace). Then it is quenched in air or oil to reach maximum hardness.

Tempering:

Subsequently, the quenched steel is tempered at 540-560°C for at least two cycles (≥ 2 h) to achieve toughness and stability while keep CHP high hardness.

T1 high-speed steel has the following properties after appropriate heat treatment:

Outstanding Hardness: Hardness range of 63-64 HRC, providing excellent cutting performance.

Exceptional Resistance To Wear: The elevated tungsten percentage results in superior wear resistance for a longer lasting tool.

Increased Red Hardness: Retains cutting ability and performance at higher temperatures.

The ability of saving without quality sacrifice

We guarantee that our T1 high-speed steel is not inferior to high-class ones from Japan, Europe and the USA at a more favorable price. By moving to proficent smelting and employing stricter standards we are able to hit top performance, at cost effective pricing.

Forefront Metallurgical Processes:

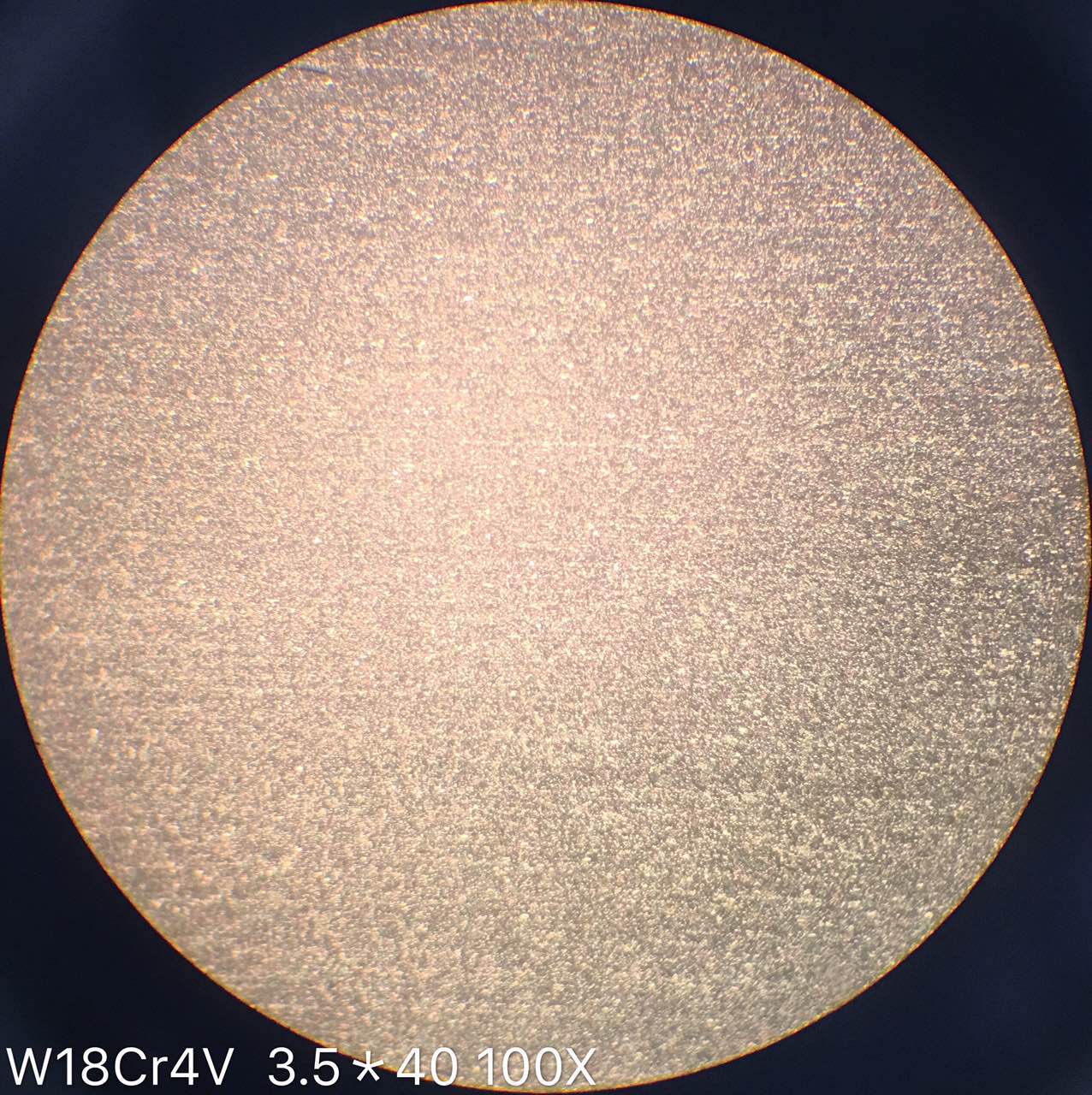

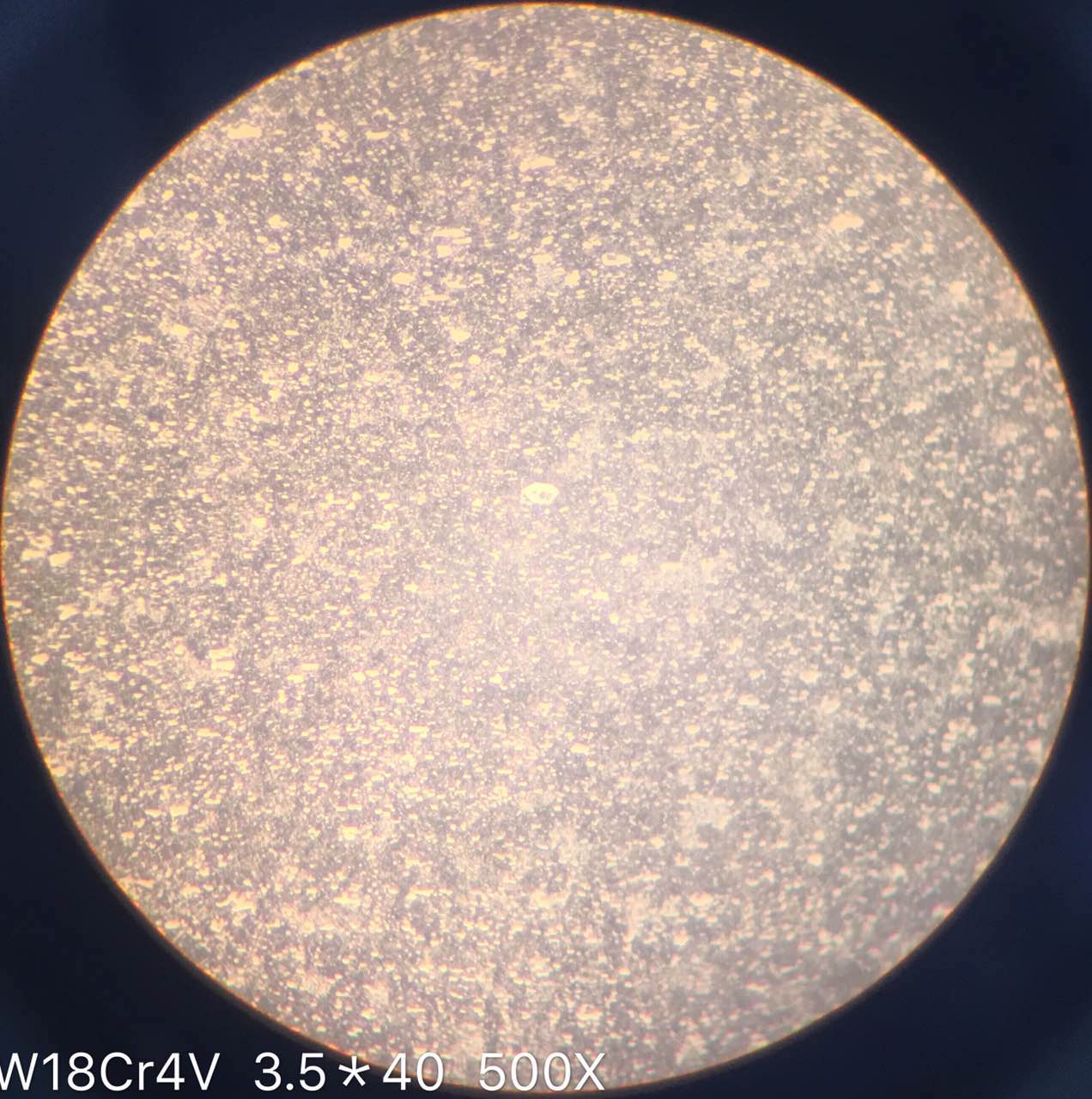

We adopt new EAF + LF + VD + RS ESR process, the heat is uniform into the microstructure, the carbide distribution more fine. This improves T1 high-speed steel toughness, the wear-resistant and overall performance.

Heat treatment with precision control:

Applied cast hardened: Our optimized heat-treatment process provides T1 steel with optimal red hardness, hardness retention, and wear resistance in high-speed cutting.

Our products have reliable and stable quality

Consistent Material Quality:

Raw material selection, processing, and quality inspection are all in our hands, meaning we can deliver consistent and repeatable quality of each batch of T1 high-speed steel.

Adheres to International Quality Standards:

High speed steel T1 is complied with a series of international standards as GB/T 9943-2008, AISI T1, JIS SKH2 and DIN 1.3355.

Chemical composition, hardness, toughness and microstructure are tested with high accuracy in advanced testing equipment. Such high standards of quality control guarantee that each batch is consistent and dependable.

Leading Research & Development:

We work with Shanghai University and Beijing Iron & Steel Research Institute on national high-performance materials research and on independent R&D of the exclusive Rapid Solidification Electro-Slag Remelting (RS ESR) technology to improve materials in terms of purity and performance.

Exclusive Proprietary Technology:

Together withShanghai University and Beijing Iron & Steel Research Institute, we developed a proprietary Rapid Solidification Electro-Slag Remelting (RS ESR) process to greatly enhance T1 purity and carbide distribution.

T1 is 100% tungsten-based while molybdenum-based HSS, such as M2, is not. Making it particularly suitable for applications requiring extreme wear resistance, high-speed cutting, and long tool life.

The T1, W18Cr4V1, SKH2, and 1.3355 high-speed steels are widely-used in applications needing high hardness, wear-resistance, and high-temperature strength. Key uses include:

Metal cutting tools (e.g., drills, milling cutters as well as lathes) for high-speed in addition to high-temperature situations.

Moulds for die-casting and stamping because of those wear-resistance.

Measuring and inspection instruments, precision tools.

Aerospace and military applications that demand strength and corrosion resistance at high temperatures.

1.Is T1 W18Cr4V1 SKH2 1.3355 High-Speed Steel available in customized specifications?

YES, We provide customized services according to the needs of customers, such as width, hardness, shape, etc. T1 W18Cr4V1 SKH2 1.3355 High-Speed Steel with varied production processes and applications can be fully customized in our business.

2.Maintenance of T1 W18Cr4V1 SKH2 1.3355 High-Speed Steel tools.

Regular monitoring of tool-sharpness and maintenance-related grinding is recommended for optimal performance of the tool. When cutting, it’s critical to control the cutting temperature, minimize heat load, and employ suitable cooling that helps extend the tool’s life. We provide a comprehensive range of services, from heat treatment to post-processing, which facilitates maintenance and tool optimization tailored to your requirements

3. What services does your company provide, and why should I choose to work with you?

We are not only the first-class raw material provider but also the raw material supply and finished product processing one-stop service suppliers. Custom processing, heat treatment, product delivery, high quality products, fast delivery time. We offer integrated services that help our clients eliminate outsourcing jobs, speed up production cycles, and cut time and cost.

4.How do you ensure product quality?

We also have strict quality control procedures at all stages — from raw material purchase and production processing to shipment delivery. All items conform to industry criteria and go through comprehensive screening and verification. We also offer T1 W18Cr4V1 SKH2 1.3355 High-Speed Steel above and beyond what meets the high needs of the clients; heat treatment, post-processing, and other value-added providers. We provide better quality and economical products through our systematic approach.

Contact us by email zeicin@zeicin.com