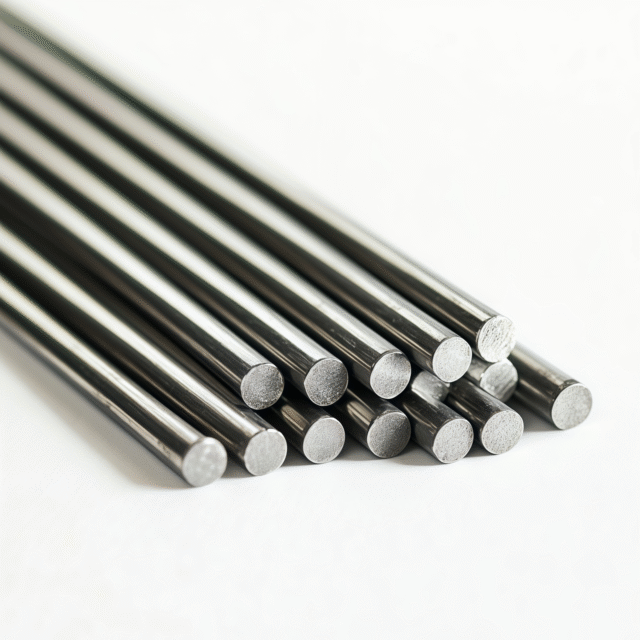

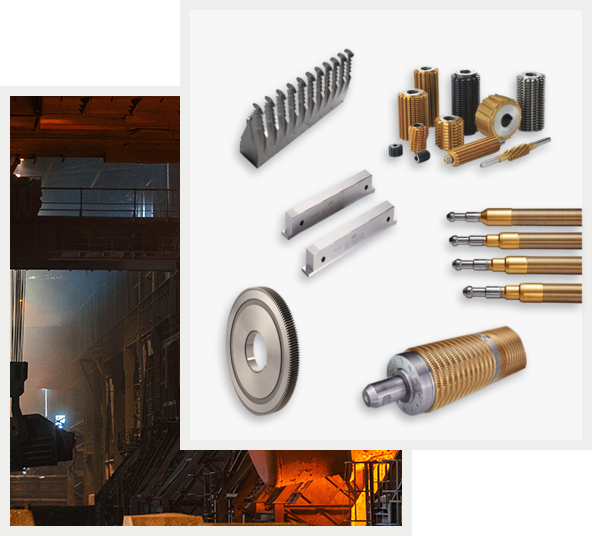

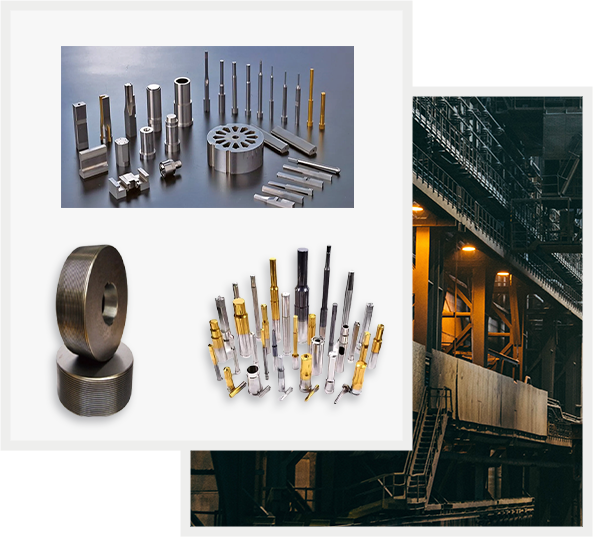

W18/SKH2 high-speed steel round bar is a high-performance tool steel known for its excellent wear resistance, high hardness, and high-temperature performance. It is widely used in precision cutting tools, drill bits, end mills, and other high-strength machining applications. This material maintains outstanding hardness and sharpness even in high-temperature environments, effectively improving machining efficiency and extending tool life. Whether in mechanical processing or precision manufacturing, W18/SKH2 high-speed steel round bar is an ideal choice, offering exceptional wear resistance and long-lasting stability.

| ZEICIN Grade | GB | ISO | AISI | DIN | JIS |

| W18 | W18Cr4V | HS18-0-1 | T1 | 1.3355 | SKH2 |

| C | W | Mo | Cr | V | Co | Al | Mn | Si | S | P |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.73-0.83 | 17.20-18.70 | / | 3.80-4.50 | 1.00-1.20 | – | – | 0.10-0.40 | 0.20-0.40 | ≤0.03 | ≤0.03 |

| Type | Specification(mm) | Surface Condition |

|---|---|---|

| Cold-drawn Round Steel | φ2-10 | Black |

| Hot-rolled Round Steel | φ11-75 | Turned |

| Precision Forging Round Steel | φ80-120 | Turned |

| TW | 20 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|

| 3 | √ | √ | √ | √ | ||||||

| 4~5 | √ | √ | √ | √ | √ | √ | ||||

| 6~13 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 14 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 15~18 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 19 | √ | √ | √ | √ | √ | √ | √ | |||

| 20 | √ | √ | √ | √ | √ | √ | √ | √ |

1. Excellent Hot Hardness and Wear Resistance

W18 / SKH2 high-speed steel round bar offers excellent hot hardness and wear resistance, making it suitable for high-speed cutting tools and heavy-duty machining applications.

2. Reliable Toughness and Stable Performance

With a balanced chemical composition, W18 / SKH2 provides good toughness and stable cutting performance, reducing the risk of edge chipping during service.

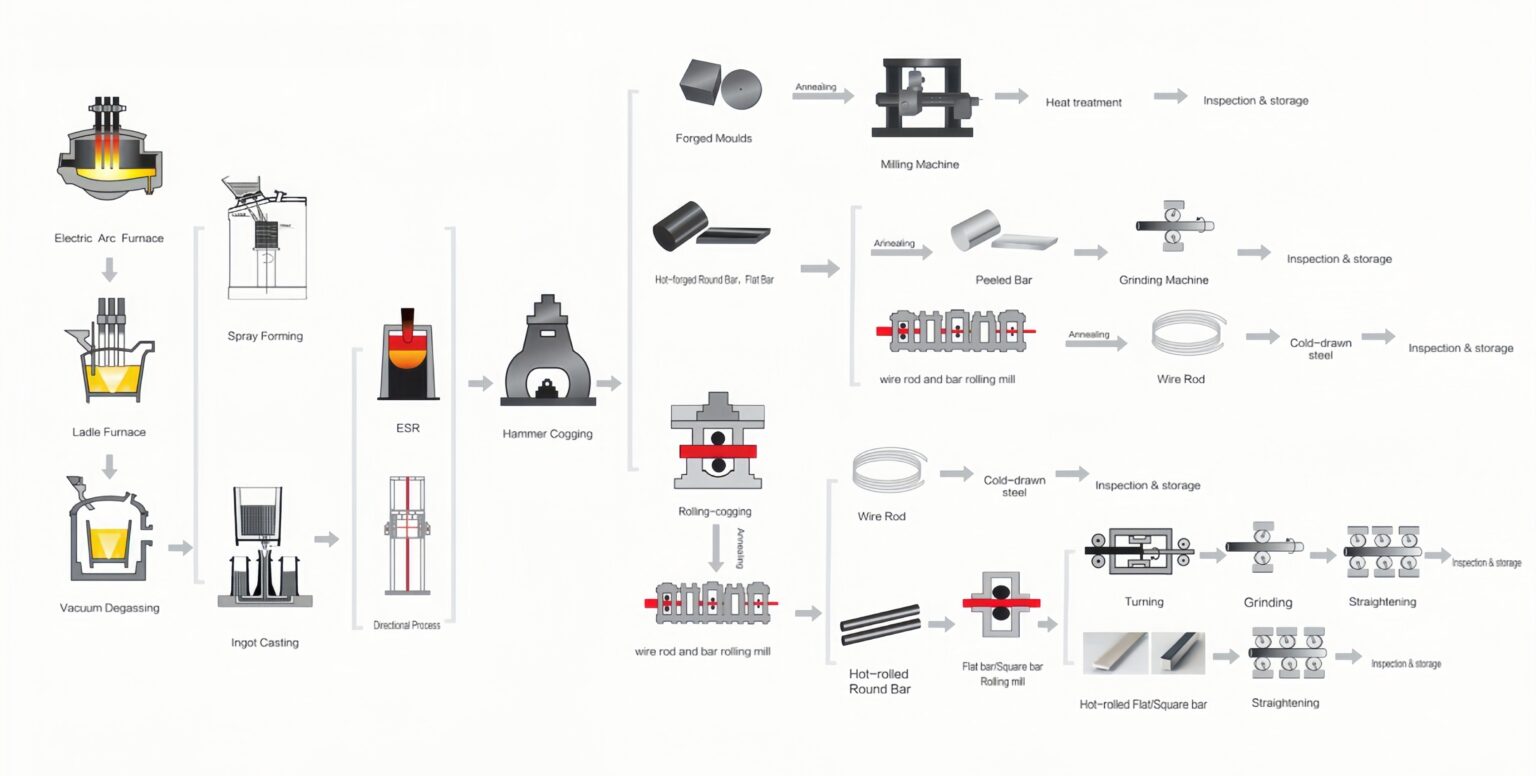

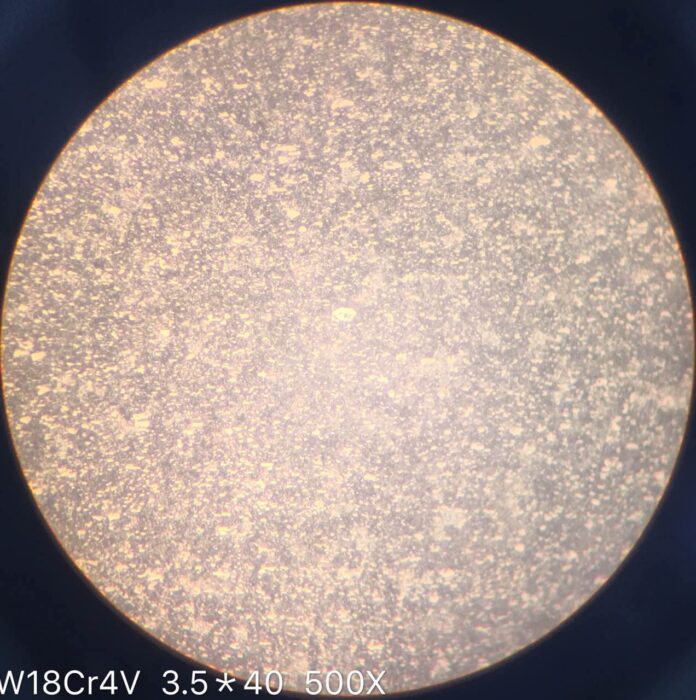

1. Mature High-Speed Steel Production Process

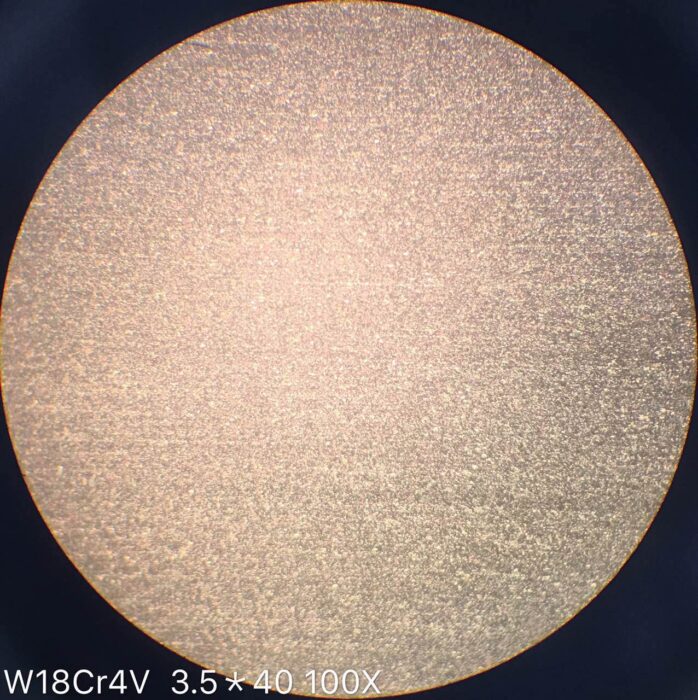

W18 / SKH2 is produced using a mature and proven high-speed steel manufacturing process, ensuring stable structure and consistent carbide distribution.

2. Reliable Heat Treatment Performance

After proper heat treatment, W18 / SKH2 achieves high hardness and good thermal stability, ensuring long tool life under high-temperature cutting conditions.

1. Stable Quality Control

Strict process control and inspection ensure consistent mechanical properties and reliable performance across different batches.

2. International Standards Compliance

W18 / SKH2 high-speed steel complies with major international standards such as ASTM, DIN, JIS, and GB, and is widely used in the cutting tool industry.

The W18 high-speed steels are widely used in applications needing high hardness, wear-resistance, and high-temperature strength. Key uses include:

Q1: Do you accept trial orders?

A1: Yes, we accept trial orders, provided that the required size and model are in stock.

Q2: What is your delivery time?

A2: If the products are in stock, the delivery time is generally 5-15 days. If the products are out of stock, the delivery time may range from 15 to 20 days, depending on the order quantity.

Q3: Do you offer discounts for bulk orders?

A3: Yes, we offer discounts for bulk orders. The specific discount will depend on the order quantity and the terms of cooperation. Please do not hesitate to contact us for more information.

Q4: What is your product packaging like?

A4: Our products are packaged in standard industrial packaging to ensure safety during transportation. If you have specific packaging requirements, please let us know when placing the order, and we will package your items accordingly.

Q5: What payment methods do you support?

A5: We accept a variety of payment methods, including T/T, L/C, Alipay, PayPal, etc. The specific payment method can be arranged flexibly based on the order amount and customer needs.